An impeller serves as a vital component in pumps and compressors, playing a key role in fluid movement. It works by using centrifugal action to increase both pressure and flow, ensuring efficient operation in various systems.

Commonly found in centrifugal pumps, impellers transfer energy from the motor to the fluid, enabling smooth and consistent performance. This process is essential for applications involving water and other fluids, making impellers indispensable in many industries.

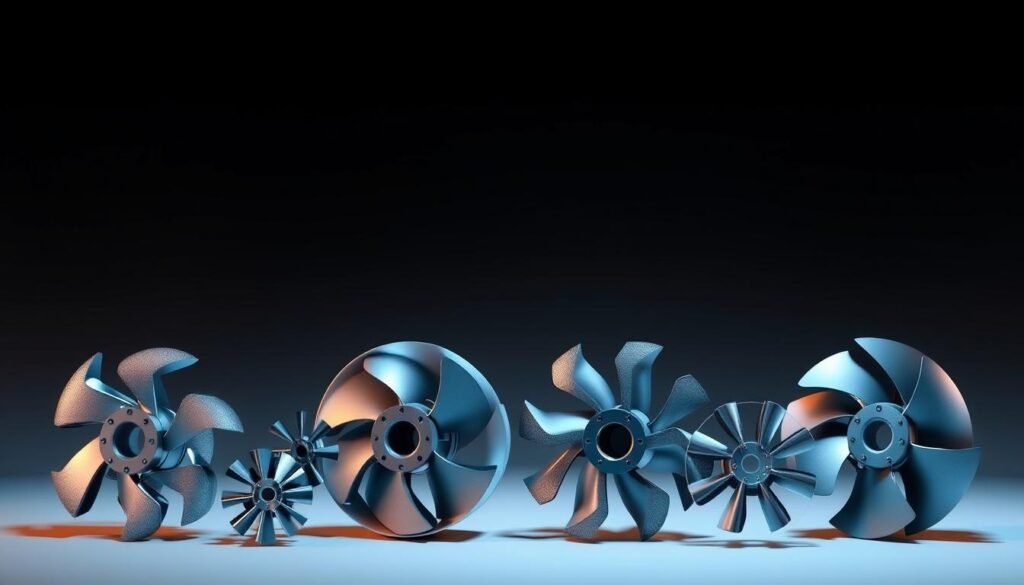

While impellers and turbines share similarities, they serve distinct purposes. Propellers, a sub-class of impellers, are designed for specific tasks. This article will explore the types, дизайн, selection criteria, and maintenance of impellers to provide a comprehensive understanding of their importance.

Understanding Impeller Fundamentals

At the heart of many pumping systems lies the impeller, a critical part for fluid movement. This rotating component plays a vital role in converting mechanical energy into fluid motion, ensuring efficient operation across various applications.

Definition and Core Functions

An impeller is a rotating component within a pump that accelerates fluid from the center, or eye, outward. This process relies on centrifugal force, which increases both pressure and flow. The design of the vanes, their shape, and arrangement significantly influence the system’s efficiency.

There are three primary types of impellers: открыть, полуоткрытый, and closed. Each type has its benefits and limitations, making them suitable for specific applications. Например, closed impellers are ideal for handling clean liquids, while semi-open designs are better for fluids with solid particles.

Обзор приложений рабочего колеса

Impellers are used in a wide range of systems, from water pumps to air compressors. Their ability to handle different fluids and pressures makes them versatile components in industries like agriculture, Производство, and HVAC.

- Water Pumps: Impellers ensure consistent water flow in irrigation and drainage systems.

- Air Compressors: They help compress air for industrial and commercial use.

- Химическая обработка: Impellers handle corrosive and abrasive fluids efficiently.

Understanding the fundamentals of impellers is essential for selecting the right type and ensuring optimal performance in any system.

What is an impeller: Its Role in Enhancing Pump Performance

The efficiency of a pump largely depends on the impeller, a component that drives fluid movement through centrifugal force. This rotating part converts mechanical energy from the motor into kinetic energy, enabling the pump to transfer liquids effectively.

Centrifugal force is the key principle behind an impeller’s function. Поскольку рабочее колесо вращается, it accelerates the fluid outward, increasing its velocity. This high-speed stream is then converted into pressure within the pump casing, ensuring smooth discharge.

“The integration of advanced technology in impeller design has revolutionized pump efficiency, allowing for precise control over flow and pressure.”

Conversion of Mechanical Energy into Fluid Motion

Impellers play a critical role in transforming motor energy into fluid motion. The rotation of the vanes creates a dynamic pressure increase, which is essential for maintaining consistent flow rates. Proper design ensures minimal energy loss and optimal performance.

Understanding pump performance curves is vital. These curves illustrate the relationship between flow rate, давление, и эффективность. Adjusting impeller characteristics, such as vane shape and size, can significantly enhance these metrics.

| Impeller Characteristic | Impact on Pump Performance |

|---|---|

| Vane Shape | Influences flow rate and efficiency |

| Размер | Affects pressure and discharge capacity |

| Материал | Determines durability and resistance to wear |

Например, a well-designed impeller in a centrifugal pump can handle high flow rates while maintaining low energy consumption. This balance is crucial for industries requiring reliable and efficient fluid transfer systems.

In summary, the impeller’s ability to convert energy and manage flow makes it indispensable in pump technology. Its design and function directly impact the overall work output, ensuring systems operate at peak performance.

Types and Design Variations of Impellers

Impellers come in various designs, each tailored to specific operational needs. The choice of design directly affects the efficiency, долговечность, and application of the pump. Understanding these variations is crucial for selecting the right component for your system.

Открыть, Полуоткрытый, и закрытые побочки

Open impellers feature visible vanes without shrouds, making them simple and easy to maintain. They are ideal for handling liquids with suspended solids, such as wastewater. Однако, their open structure can lead to higher recirculation losses.

Semi-open impellers include a shroud on one side, adding mechanical strength. This design improves efficiency and is suitable for high-pressure applications. It strikes a balance between the simplicity of open impellers and the robustness of closed designs.

Закрытые носители имеют скручивание с обеих сторон, reducing recirculation losses and enhancing efficiency. They are best for clean liquids and high-performance systems. Their complex design, though, makes them harder to maintain.

Specialty Designs: Vortex and Cutter Impellers

Vortex impellers are designed to handle debris and stringy solids. They create a vortex flow that minimizes clogging, making them ideal for wastewater treatment and marine systems.

Cutter impellers feature sharp blades that shred solids before pumping. These are commonly used in industrial applications where debris-laden liquids are prevalent. Their robust design ensures smooth operation in challenging environments.

Blade design and speed play a critical role in determining a pump’s flow characteristics. Curved blades, for example, enhance flow efficiency, while straight blades are better for high-speed operations. Selecting the right combination ensures optimal performance in water treatment, marine, and industrial systems.

How to Select and Customize Your Impeller

Selecting the right impeller is crucial for optimizing pump performance and ensuring system efficiency. The choice depends on factors like fluid type, flow rate, and pressure requirements. Engineers must evaluate these parameters to achieve the desired balance between energy transfer and operational durability.

Factors Influencing Impeller Choice

Fluid characteristics play a key role in impeller selection. Например, clean liquids work best with closed designs, while semi-open impellers handle solids more effectively. The flow rate and pressure requirements of the application also dictate the ideal design.

Pump performance curves are essential tools for precise selection. These curves illustrate the relationship between flow rate, давление, и эффективность. Matching the impeller to the correct duty point ensures optimal energy usage and minimizes wear.

Impact of Impeller Diameter and Trim

Adjusting the impeller diameter or trimming its edges can fine-tune pump performance. Trimming is a cost-effective alternative to frequency drives but requires caution. Increasing clearance can reduce efficiency, so modifications must be carefully calculated.

Small changes in diameter or vane shape can lead to significant differences in flow and pressure. Например, reducing the diameter lowers the flow rate but increases pressure, making it ideal for high-pressure applications.

“Precise impeller customization ensures that pumps operate at peak efficiency, reducing energy consumption and extending system lifespan.”

When handling abrasive liquids or solids, durability becomes a priority. Engineers must weigh the trade-offs between efficiency and the risk of damage. Specialty designs like vortex or cutter impellers are often the best choice for challenging environments.

- Evaluate fluid type: Clean liquids, abrasive fluids, or solids.

- Assess flow rate and pressure: Match impeller design to system requirements.

- Consider durability: Choose materials and designs that resist wear.

Следуя этим руководящим принципам, engineers can select and customize impellers that meet specific application needs. This ensures reliable performance, energy efficiency, and long-term system durability.

Maintenance, Troubleshooting, and Operational Efficiency

Maintaining the efficiency of a pump system relies heavily on the proper care of its impeller. Regular inspections and timely maintenance can prevent wear, extend the component’s lifespan, and ensure consistent performance. A well-maintained impeller keeps the system running smoothly, reducing energy consumption and operational costs.

Preventing Damage and Managing Wear

Inspecting the impeller blades and vanes for wear and tear is a critical step in maintenance. Look for signs of erosion, трещины, or debris buildup, which can disrupt fluid flow and reduce efficiency. Cleaning the impeller regularly prevents clogging and ensures optimal performance.

Adjusting the clearance between the impeller and pump casing is another key practice. Proper alignment minimizes energy loss and maintains pressure flow. Misalignment can lead to uneven wear and decreased system efficiency.

“Routine maintenance not only prevents damage but also enhances the overall performance of the pump system.”

Monitoring pressure and flow rates helps detect performance drops early. Sudden changes in these metrics often indicate issues like wear, debris buildup, or incorrect clearances. Addressing these problems promptly can prevent costly repairs and downtime.

Best Practices for Cleaning and Maintenance

Follow these steps to keep your impeller in top condition:

- Inspect Regularly: Check for wear, трещины, and debris buildup.

- Clean Thoroughly: Remove any solids or contaminants that could clog the system.

- Adjust Clearance: Ensure proper alignment between the impeller and pump casing.

- Monitor Performance: Track pressure and flow rates to detect issues early.

Using the right tools and technology is essential for effective maintenance. Always follow manufacturer guidelines to ensure safe and reliable operation. Например, in water pump applications, regular cleaning prevents sediment buildup, while in air compressors, proper lubrication reduces wear.

Balancing the impeller’s design attributes, such as blade shape and flow rate, with the system’s energy and pressure requirements is crucial. A well-maintained impeller ensures efficient fluid transfer, reduces energy consumption, and extends the system’s lifespan.

Заключение

Understanding the role of impellers in fluid transfer is essential for optimizing pump systems. This article explored various types, including open, полуоткрытый, and closed designs, each suited for specific applications. Selecting the right type ensures efficiency and prevents damage.

Proper maintenance is crucial for sustaining performance. Regular inspections and cleaning reduce wear, keeping the system running smoothly. Adjusting blade clearance and monitoring pressure flow further enhance operational reliability.

Technological advancements and design variations, such as vortex and cutter impellers, offer tailored solutions for challenging environments. Applying these insights ensures efficient fluid handling and extends the system’s lifespan.

Review maintenance tips and selection criteria when planning upgrades or new installations. This approach guarantees reliable and efficient pump operations, meeting diverse industrial needs.