Impeller failure in turbomachinery can lead to big problems. These include lower efficiency, more downtime, and higher maintenance costs. It’s key to know why impellers fail, like due to mechanical stress, cavitation, or material wear.

Looking into why impellers fail is crucial for turbomachines to work better and last longer. By finding out why failures happen, operators can stop them before they start. This helps avoid expensive fixes and keeps turbomachines running smoothly.

To really understand impeller failure, you need to know how turbomachinery parts work together. By spotting where failures might happen and taking steps to prevent them, operators can keep their machines running well. This is vital for keeping turbomachines efficient and preventing failures.

Understanding Turbomachinery Impeller Systems

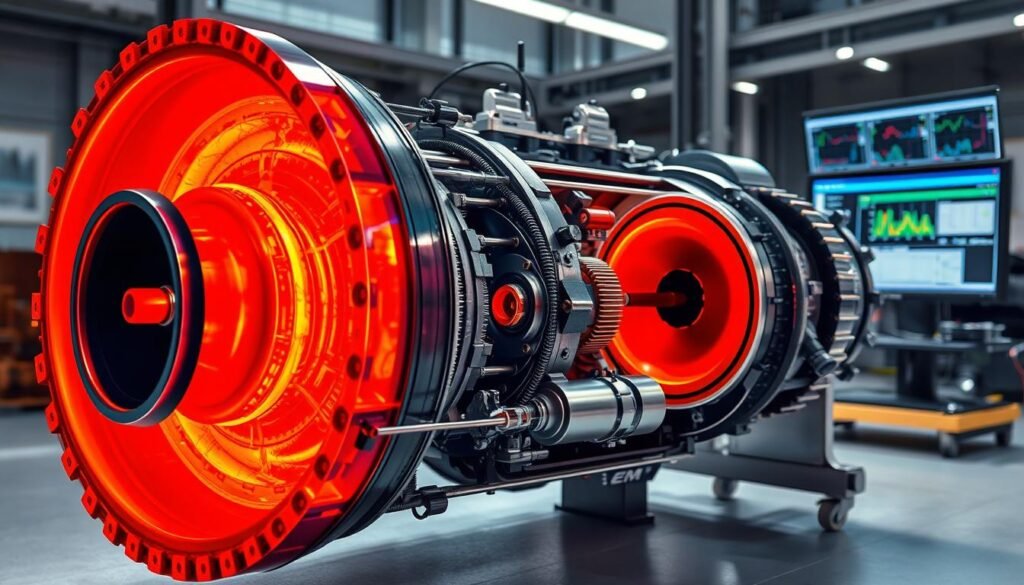

Turbomachinery impeller systems are complex. They need precise impeller design and operation for the best performance. The key parts are the blades, hub, and shroud. Each part is crucial for fluid flow and energy transfer.

When doing a failure analysis, we must look at fluid dynamics, materials science, and mechanical engineering. The impeller’s speed, pressure, and temperature matter a lot. So do design details like blade angle and pitch.

Critical Components of Impeller Assembly

- Blades: responsible for transferring energy to the fluid

- Hub: connects the blades and provides structural support

- Shroud: surrounds the blades and helps to direct the fluid flow

Operating Parameters and Design Specifications

Knowing the impeller’s operating parameters and design specs is key for failure analysis. It helps in designing impellers that meet certain performance and operational needs. The impeller design must be optimized for the best performance and efficiency.

Performance Requirements and Operational Limits

The performance needs and operational limits of an impeller are very important. They help determine its reliability and efficiency. By understanding these, engineers can design impellers that meet specific needs. This reduces the chance of failure analysis and boosts system performance.

Common Mechanisms of Impeller Failure

Impellers in turbomachinery face several failure mechanisms. Each has its own causes and effects. Understanding these helps in creating better preventive maintenance and performance optimization plans. This way, operators can prevent failures and make impellers last longer.

The main reasons for impeller failure include:

- Mechanical stress and fatigue, which can lead to cracking and eventual failure

- Cavitation and erosion, causing significant damage to the impeller blades and surfaces

- Material degradation, compromising the structural integrity of the impeller due to corrosion, wear, or other factors

- Operational overload, resulting from excessive speeds, pressures, or flows, leading to premature failure

By tackling these issues with preventive maintenance and performance optimization, operators can lower the chance of impeller failure. Regular checks and inspections can spot problems early. This allows for quick fixes and less downtime.

A detailed maintenance plan that includes preventive maintenance and performance optimization can reduce impeller failure risks. This ensures turbomachinery works reliably. By focusing on maintenance and optimization, operators can cut downtime, lower costs, and boost efficiency.

Diagnostic Techniques for Early Detection

Early detection of potential failures is crucial for preventing downtime and cutting maintenance costs in turbomachinery. Diagnostic techniques like vibration analysis, thermal imaging, and performance monitoring help spot early signs of impeller failure. These methods help check the condition of the impeller and other key parts, respond to changes, and stop unexpected failures.

Condition monitoring systems, whether offline or online, are vital for continuously checking the health of the impeller and other critical parts. By using these diagnostic techniques and condition monitoring strategies, operators can act early to fix issues before they become big problems. This ensures the turbomachine’s reliability and efficiency.

Some common diagnostic techniques used in turbomachinery include:

- Vibration analysis

- Thermal imaging

- Performance monitoring

These methods help find early signs of impeller failure, like increased vibration, temperature changes, and lower performance.

By adding condition monitoring and diagnostic techniques to their maintenance routine, operators can cut downtime, extend equipment life, and improve overall system performance.

Implementing Preventive Maintenance Strategies

Preventive maintenance is key to avoiding impeller failure in turbomachinery. It combines condition monitoring, scheduled inspections, and performance tests. This ensures your equipment works well and reliably. Regular scheduled inspection spots problems early, so you can fix them fast and avoid long stops.

Some important preventive maintenance steps are:

- Condition monitoring systems to track the impeller and other parts’ health in real-time

- Scheduled inspection protocols, like looking over the impeller, checking its size, and testing materials

- Performance tests, like measuring flow rates and efficiency, to see how the impeller and turbomachine are doing

Using these methods in a full maintenance plan cuts downtime, makes the impeller last longer, and boosts turbomachinery’s reliability and efficiency. Performance testing is vital, as it shows where improvements are needed and keeps the equipment running at its best.

To make preventive maintenance work, you need to be proactive. Focus on constant monitoring, inspections, and tests. This way, you lower the chance of impeller failure and keep your turbomachinery running smoothly.

| Maintenance Strategy | Benefits |

|---|---|

| Condition Monitoring Systems | Real-time data on equipment health, reduced downtime |

| Scheduled Inspection Protocols | Early identification of potential issues, minimized risk of failure |

| Performance Testing Methods | Optimized equipment performance, improved efficiency |

Conclusion: Optimizing Impeller Reliability and Performance

Keeping impellers in top shape is crucial for smooth operation and less downtime. This article offers key insights to help turbomachinery operators avoid impeller failures. It also boosts system productivity.

Understanding why impellers fail is the first step. Issues like mechanical stress, cavitation, and material wear can be tackled with the right maintenance. Advanced diagnostics and regular checks are essential. This way, impellers last longer, making systems more reliable and efficient.

The turbomachinery field is always changing. Staying ahead in impeller performance is vital for success. By following the advice in this article, professionals can improve their maintenance skills. This leads to better operations overall.