An impeller is the rotating component of a pump that plays a critical role in transferring energy from the motor to the liquid. This process generates the necessary flow and pressure to move fluids efficiently. Without impellers, pumps would struggle to perform their core functions in various industrial and technical applications.

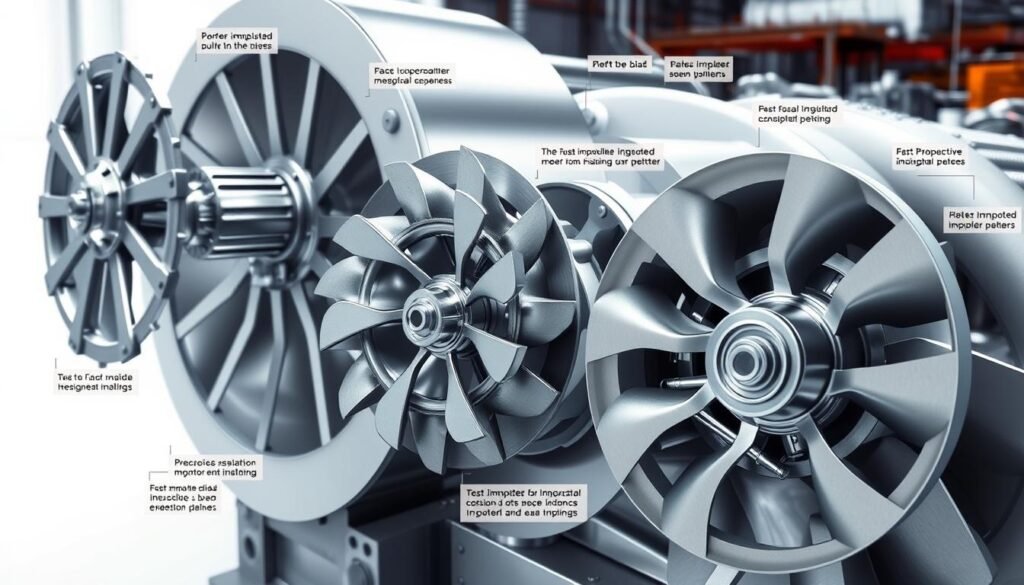

Impellers come in different designs, each tailored to specific needs. The three primary types are open, semi-open, and closed. Open impellers lack a shroud, making them ideal for handling liquids with solids. Semi-open impellers feature a partial shroud, balancing efficiency and durability. Closed impellers, with full shrouds, are known for their high efficiency in clean liquid applications.

Understanding these variations is essential for selecting the right impeller for your pump system. Factors like vane design, material, and size directly impact performance. This guide will explore these aspects, helping you make informed decisions for optimal pump operation.

Understanding Impeller Basics

The heart of any pump system lies in its impeller, a component designed to move fluids efficiently. This rotating part is crucial for transferring energy from the motor to the liquid, ensuring smooth operation across various applications.

What is an Impeller?

An impeller is the rotating element within a pump that generates flow and pressure. It consists of vanes or blades attached to a central shaft. These vanes push the fluid outward, creating the necessary force to move it through the system.

Impeller Role in Pump Performance

Impellers play a vital role in pump performance by converting mechanical energy into fluid energy. This process relies on centrifugal force, which propels the liquid outward from the center. The design of the impeller directly impacts efficiency, pressure, and flow rates.

Different applications require specific impeller designs. For example, open impellers are ideal for handling liquids with suspended solids, such as wastewater. Closed impellers, on the other hand, excel in clean liquid applications due to their high efficiency.

The geometry of the impeller, including the shape and number of vanes, also affects performance. Proper design tolerance and operational clearances ensure minimal wear and maintenance, extending the pump’s lifespan.

Exploring Impeller Design and Materials

The design and material of an impeller significantly influence its performance in various applications. Understanding these factors helps in selecting the right pump impeller for specific needs, ensuring efficiency and durability.

Design Variations: Open, Semi-Open, and Closed

Impellers come in three primary designs, each suited for different tasks:

- Open Impeller: Features vanes without shrouds, making it ideal for handling liquids with solids. It’s commonly used in wastewater applications.

- Semi-Open Impeller: Includes a partial shroud, balancing efficiency and durability. It’s versatile for both clean and slightly contaminated fluids.

- Closed Impeller: Has full shrouds on both sides, offering high efficiency for clean liquids. It’s preferred in applications like water supply systems.

Each design impacts flow, pressure, and overall pump performance. For instance, vane shape and shroud size determine how effectively the impeller moves the fluid.

Material Selection and Durability

Choosing the right material is crucial for impeller longevity and performance. Common materials include:

- Stainless Steel: Resistant to corrosion and abrasion, suitable for harsh environments.

- Bronze: Offers excellent resistance to saltwater, making it ideal for marine applications.

- Cast Iron: Cost-effective and durable, often used in general-purpose pumps.

Specialized materials like gunmetal are used for salt handling, while polymer-coated impellers are effective for acidic liquids. Material choice directly affects wear resistance and operational costs.

Design factors such as vane geometry and shroud size also play a role in performance. Proper clearances and tolerances ensure minimal wear, enhancing the pump’s lifespan. Additionally, parameters like NPSH and flow efficiency are critical for optimal operation.

How many types of impeller: Overview and Applications

Impellers are essential components in pumps, designed to handle various fluid dynamics and operational demands. Their design and application vary significantly across centrifugal, sewage, and process pumps, ensuring optimal performance in diverse environments.

Impeller Types in Centrifugal, Sewage, and Process Pumps

Centrifugal pumps often use closed impellers for clean liquids, ensuring high efficiency and minimal wear. These impellers are ideal for applications like water supply systems, where consistent flow and pressure are critical.

Sewage pumps, on the other hand, rely on open or semi-open impellers to handle solids and debris in wastewater. The absence of a full shroud allows these impellers to pass solids without clogging, making them indispensable in municipal and industrial wastewater treatment.

Process pumps, used in industries like chemical and food processing, require impellers tailored to specific fluid properties. Semi-open impellers are commonly used here, balancing efficiency and durability for liquids with varying viscosities and contaminants.

“The right impeller design can significantly enhance pump efficiency and reduce maintenance costs.”

| Pump Type | Impeller Design | Key Applications |

|---|---|---|

| Centrifugal | Closed | Water supply, clean liquids |

| Sewage | Open/Semi-open | Wastewater treatment, solids handling |

| Process | Semi-open | Chemical processing, food industry |

Fluid dynamics play a crucial role in impeller selection. For instance, the presence of solids in wastewater demands robust designs like open impellers, while clean liquids benefit from the efficiency of closed impellers. Understanding these dynamics ensures the right impeller choice for each application.

Performance advantages vary by impeller type. Closed impellers offer high efficiency and low maintenance, while open impellers excel in handling solids. Semi-open impellers provide a versatile solution for applications requiring a balance between efficiency and durability.

Key parameters like flow characteristics, pressure generation, and compatibility with pump casings are critical in impeller selection. For example, the size and shape of the impeller vanes directly impact flow rates and operational pressure.

Technical examples illustrate these differences. In centrifugal pumps, closed impellers achieve consistent flow, while sewage pumps with open impellers handle debris effectively. Process pumps with semi-open impellers adapt to varying fluid properties, ensuring reliable performance.

Understanding these applications prepares readers for exploring operational performance values in the next section, where factors like efficiency and pressure optimization will be discussed in detail.

Operational Performance and Efficiency Factors

Efficiency in pump systems hinges on the impeller’s operational performance. Factors like flow rates, pressure, and NPSH play a critical role in determining how effectively a pump operates. Understanding these elements ensures optimal energy use and reduces waste.

Centrifugal Pump Efficiency and NPSH Considerations

In centrifugal pumps, efficiency is closely tied to the impeller’s design and operational conditions. Net Positive Suction Head (NPSH) is a key factor, ensuring the pump operates without cavitation. Proper NPSH values prevent damage and maintain consistent performance.

Trimming the impeller vanes can optimize pump efficiency. Reducing the impeller diameter lowers flow and pressure, aligning the pump with specific operational needs. This adjustment minimizes energy consumption while maintaining desired performance levels.

Optimizing Flow and Pressure

Affinity laws provide a framework for understanding how changes in impeller speed and diameter affect pump performance. These laws state that flow is proportional to speed, pressure to the square of speed, and power to the cube of speed. Applying these principles allows for precise adjustments.

For example, reducing impeller speed by 10% decreases flow by 10%, pressure by 19%, and power by 27%. Such adjustments are invaluable in applications like water supply systems, where energy efficiency is critical.

| Performance Factor | Impact of Impeller Adjustment |

|---|---|

| Flow | Proportional to speed |

| Pressure | Proportional to speed squared |

| Power | Proportional to speed cubed |

Real-life examples highlight the benefits of these adjustments. In wastewater treatment, trimming open impellers improves solid handling while maintaining flow. In clean liquid applications, closed impellers achieve high efficiency with minimal wear.

Balancing performance requirements with maintenance considerations ensures long-term reliability. Proper clearances and material selection further enhance impeller durability, reducing operational costs.

Impeller Selection: A How-To Guide

Selecting the right impeller is a critical step in ensuring optimal pump performance and longevity. The choice depends on factors like material, fluid properties, and compatibility with the pump system. This guide will walk you through the key considerations and techniques to make an informed decision.

Key Factors in Selecting the Right Impeller

When choosing an impeller, consider the following:

- Material: Stainless steel is ideal for corrosive environments, while bronze suits marine applications. Cast iron offers a cost-effective option for general use.

- Fluid Properties: Open impellers handle solids in wastewater, while closed impellers are best for clean liquids.

- Pump Compatibility: Ensure the impeller matches the pump’s size, shaft, and clearance requirements.

Sizing, Compatibility, and Trimming Techniques

Proper sizing ensures the impeller fits the pump casing without excessive clearance. Trimming the impeller vanes can adjust flow and pressure to meet specific needs. For example, reducing the diameter lowers energy consumption while maintaining performance.

Evaluating Cost and Maintenance Requirements

Balancing cost and performance is essential. While closed impellers offer high efficiency, they may require more frequent maintenance in harsh environments. Open impellers, on the other hand, are durable but less efficient. Consider long-term maintenance costs when making your choice.

“The right impeller choice can significantly reduce operational costs and extend pump lifespan.”

By evaluating these factors, you can select the right impeller for your application, ensuring efficient and reliable pump operation.

Maintenance and Troubleshooting Best Practices

Effective troubleshooting ensures smooth pump operation and longevity. Addressing common impeller issues like cavitation, wear, and vibration is essential for maintaining peak performance. Regular maintenance prevents costly failures and extends the lifespan of your pump system.

Identifying Common Impeller Issues

Impellers often face problems such as clogging, corrosion, and excessive vibration. Cavitation, caused by low suction pressure, can damage vanes and reduce efficiency. Wear rings and shaft imbalance also contribute to pump failure, leading to increased maintenance costs.

For example, in centrifugal pumps, improper clearance between the impeller and casing can cause wear and tear. Regular inspections help identify these issues early, preventing major breakdowns.

Preventive Maintenance Strategies

Routine maintenance is key to avoiding impeller problems. Start with regular cleaning to remove debris that can clog the passage. Inspect wear rings and vanes for signs of degradation, replacing them as needed.

Matching maintenance routines to the design of the impeller is crucial. For instance, open impellers require more frequent cleaning to handle solids, while closed impellers benefit from precise clearance checks.

Addressing Cavitation, Wear, and Vibration

To combat cavitation, ensure proper suction pressure and check for blockages in the channel. Reducing vibration involves balancing the impeller and inspecting the shaft for alignment issues.

For wear-related problems, replace damaged components like vanes or shrouds promptly. Using durable materials like stainless steel can also minimize wear in harsh environments.

“Proactive maintenance not only enhances performance but also reduces operational costs.”

By following these best practices, you can ensure your pump system operates efficiently, minimizing downtime and extending the life of your impeller.

Conclusion

Choosing the right impeller is essential for maximizing pump efficiency and longevity. Whether it’s an open impeller for handling solids in wastewater, a closed impeller for clean fluids, or a semi-open impeller for versatile applications, each design offers unique advantages. Material selection, such as stainless steel or bronze, further enhances durability and performance.

Operational factors like pressure, NPSH, and flow rates play a critical role in achieving optimal results. Proper maintenance, including regular inspections and addressing issues like wear rings or cavitation, ensures smooth operation and reduces downtime.

By considering all technical parameters—design, material, and clearance—you can select the ideal impeller for your needs. This not only improves pump performance but also lowers long-term costs. For further guidance, consult technical resources or industry experts to make informed decisions.