The fatigue strength of impellers is key in many industries, like pumps and turbines. Cast and forged impellers are used, each with its own traits. Knowing their fatigue strength is vital for reliable operation. It’s important to compare cast and forged impellers to see which is best for each job.

Cast impellers have complex shapes that can impact their strength. Forged impellers, with their uniform structure, might be stronger. The difference in strength between them matters a lot in industry.

We’ll look into how cast and forged impellers compare in strength. We’ll talk about what affects their strength, like the materials and how they’re made. By understanding these differences, we can pick the right impeller for each job. This helps make sure everything works well and lasts long.

Understanding Impeller Manufacturing Methods

Impeller manufacturing methods are key to their performance and life span. The choice of method depends on the material and the application. Casting and forging are two common methods, each with its own pros and cons.

The material of impellers is vital for their strength. Different methods lead to different materials, impacting performance. For example, casting can make materials more uniform, while forging can make them more varied.

Casting Process Overview

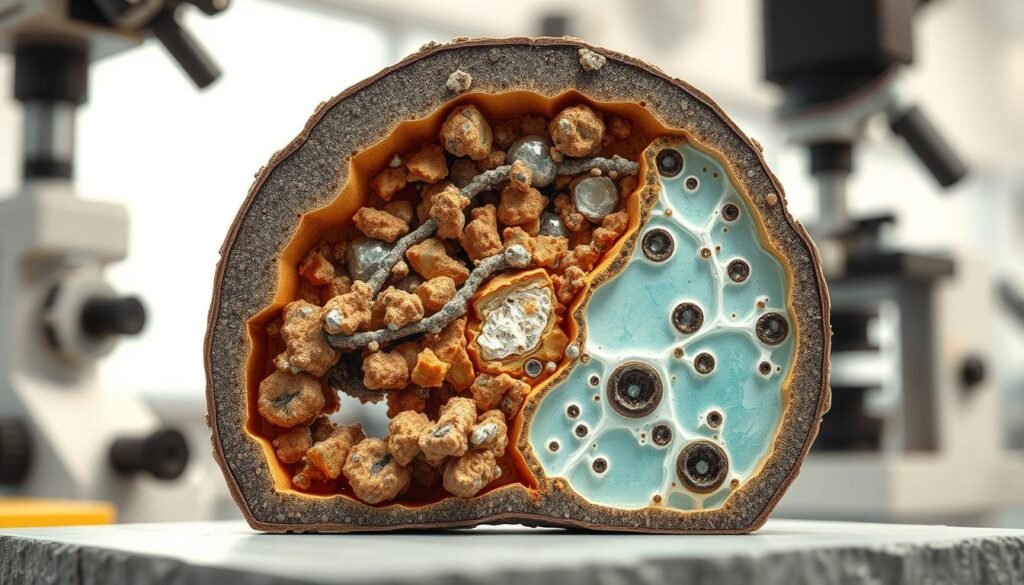

The casting process pours molten metal into a mold. It’s great for complex shapes and high accuracy. But, it can also lead to more porosity, which weakens the impeller.

Forging Technology Fundamentals

Forging shapes metal with a die and hammer. It’s better for simpler shapes and makes impellers stronger. Forging also makes materials more consistent, boosting strength.

Key Manufacturing Parameters

Several factors influence impeller material and strength. These include temperature, pressure, and time. Knowing these helps choose the best method for each application. This ensures impellers work better and last longer.

Material Composition and Microstructure Characteristics

The material of impellers is key to their strength and how they perform under stress. Optimizing material composition is vital for impellers to handle various stresses. The material’s microstructure also plays a big role in its strength, as it affects stress distribution and crack formation.

Several factors influence the material and structure of impellers:

- Alloying elements: Adding elements like chromium, nickel, and molybdenum boosts strength and resistance to corrosion.

- Heat treatment: This process changes the material’s structure and properties.

- Manufacturing process: Casting and forging methods also shape the material and structure of impellers.

It’s important to understand how material, structure, and strength are connected. By optimizing material composition and microstructure, makers can create impellers that last longer and work better under stress.

Impellers’ performance under stress also depends on their material and structure. Their ability to handle dynamic loads is tied to their material composition and microstructure. This affects their strength, toughness, and resistance to fatigue and corrosion.

Fatigue Strength Difference Analysis of Cast Impellers and Forged Impellers

The fatigue strength of impellers is key to their performance and life span. It’s affected by temperature, corrosion, and wear. Tests like rotational bending and axial fatigue are used to compare cast and forged impellers.

These tests show how stress is distributed and how impellers fail. The environment greatly affects impeller fatigue strength. For example, high temperatures and corrosive environments can shorten an impeller’s life.

Testing Methodologies

- Rotational bending tests

- Axial fatigue tests

- Stress distribution pattern analysis

- Failure mode analysis

Knowing the fatigue strength difference helps manufacturers choose the right impellers. This leads to better performance, longer life, and lower maintenance costs. Fatigue strength is vital in designing impellers for various industries.

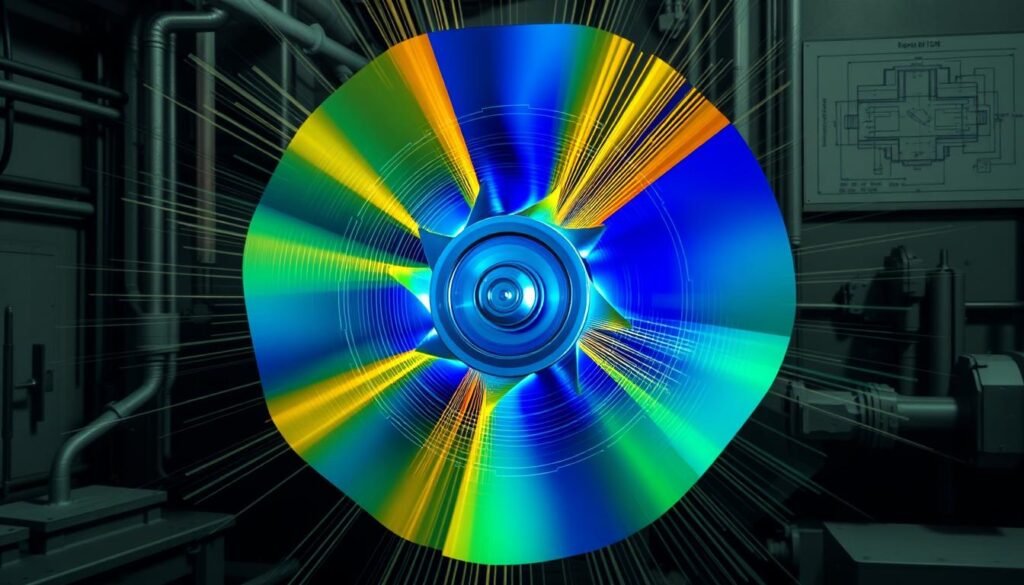

Stress Distribution Patterns

Cast and forged impellers have different stress patterns. Forged impellers have a more even stress distribution. This is because of their material and structure differences.

The environment also impacts stress patterns. It can change how stress is distributed and affect fatigue strength.

Performance Under Dynamic Loading Conditions

When it comes to dynamic loading conditions, cast and forged impellers show different performances. In industrial applications, they face changing loads. This can impact their fatigue strength and overall performance.

Material composition is key to how impellers perform under dynamic loads. Using high-strength alloys can boost fatigue strength. Design techniques, like finite element analysis, also play a role in minimizing dynamic loading effects.

Strategies for better impeller performance include:

- Using advanced materials with high fatigue strength

- Optimizing the design of the impeller using finite element analysis

- Implementing regular maintenance and inspection schedules to detect any signs of fatigue or damage

Understanding dynamic loading effects helps manufacturers create more efficient impellers. This leads to less downtime, better productivity, and longer impeller lifespans.

In conclusion, the performance of cast and forged impellers under dynamic loading conditions is vital for industrial applications. By focusing on dynamic loading effects and optimizing performance, manufacturers can make more reliable designs for today’s industry needs.

| Material | Fatigue Strength | Dynamic Loading Conditions |

|---|---|---|

| High-Strength Alloy | High | Resistant to dynamic loading |

| Cast Iron | Low | Prone to fatigue under dynamic loading |

| Forged Steel | Medium | Can withstand dynamic loading with proper design |

Impact of Operating Environment

The operating environment greatly affects the fatigue strength and performance of cast and forged impellers. Factors like temperature, corrosion, and wear play a big role. These elements can significantly impact the lifespan and efficiency of these components.

In various industrial settings, the operating environment can differ greatly. It’s vital to consider these factors when designing and selecting impellers.

The operating environment also affects the cost of owning impellers. For example, impellers exposed to high temperatures or corrosive substances may need more maintenance or replacement. This can increase costs. On the other hand, impellers designed for harsh environments can save money in the long run and perform better.

Temperature Effects

Temperature has a big impact on impeller fatigue strength. High temperatures can weaken materials, reducing strength and lifespan. Low temperatures can make materials brittle, increasing the risk of cracking and failure.

Corrosion Resistance

Corrosion resistance is key when choosing impellers for harsh environments. Impellers exposed to corrosive substances can wear out faster, leading to higher maintenance and replacement costs.

Wear Patterns

Wear patterns offer insights into impeller performance and lifespan. By studying wear patterns, manufacturers can improve impeller design for specific environments.

| Operating Environment | Impact on Fatigue Strength | Economic Considerations |

|---|---|---|

| High Temperature | Reduced strength and lifespan | Increased maintenance and replacement costs |

| Corrosive Substances | Premature wear and failure | Increased maintenance and replacement costs |

| Wear Patterns | Optimized design for specific environments | Long-term cost savings and improved performance |

Industrial Applications and Selection Criteria

Cast impellers are used in many industrial applications, like pumps and turbines. Choosing the right cast impeller depends on its strength, material, and where it will be used.

When picking cast impellers for industrial applications, consider a few key things:

- Material properties: The impeller’s material must fit the job.

- Operating conditions: It needs to handle temperature, pressure, and corrosion well.

- Performance requirements: It should meet standards for efficiency, flow, and pressure.

Cast impellers are strong, durable, and resist corrosion well. But, they might cost more and be more complex than other impellers. Engineers should weigh these points and the specific industrial applications to pick the best cast impeller.

Economic Considerations and Lifecycle Analysis

When choosing between cast and forged impellers, economic considerations are key. Forged impellers cost more to make than cast ones at first. But, their long-term benefits and durability can make up for the extra cost.

The lifecycle of cast and forged impellers shows big differences in upkeep and value over time. Here’s why forged impellers might be a better choice:

- Initial manufacturing costs: Forged impellers are pricier to make than cast ones.

- Maintenance requirements: Forged impellers need less upkeep because they last longer and resist wear better.

- Long-term value assessment: Their reliability and longer life mean big savings in the long run.

Understanding these points is vital for making the right choice. By looking at the economic considerations and lifecycle, industries can pick the best impeller for their needs. This leads to better efficiency and lower costs.

| Impeller Type | Initial Manufacturing Costs | Maintenance Requirements | Long-term Value Assessment |

|---|---|---|---|

| Cast Impellers | Lower | Higher | Lower |

| Forged Impellers | Higher | Lower | Higher |

Conclusion

The study on cast and forged impellers has shown us a lot. It tells us how important the making process, material, and where they’re used are. This helps engineers pick the right impeller for each job.

It’s clear that knowing how strong impellers are is key. They need to handle the stress of real-world use. So, makers should keep improving how they make these parts. They should look for new materials and ways to make them stronger.

As we move forward, research will help us make better impellers. These will be stronger and last longer. This will help industries work better and safer. Engineers play a big role in making this happen.