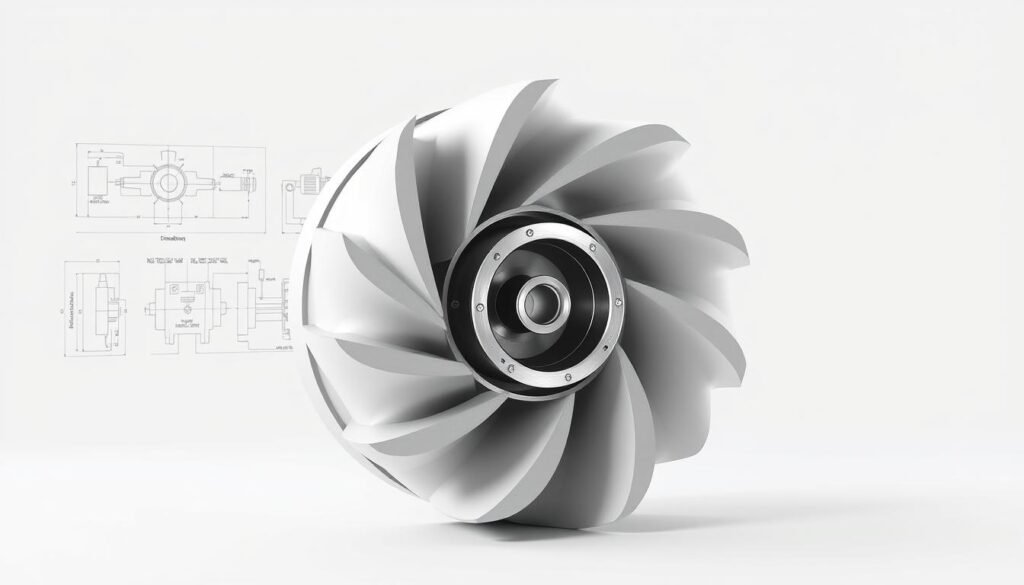

The rotating component in centrifugal systems plays a critical role in fluid movement. Known as the 임펠러, it acts as the heart of the mechanism, driving efficiency and performance. Its primary function is to transfer energy from the motor to the liquid, ensuring smooth operation.

In fluid dynamics, this part is essential for maintaining pressure and flow rates. Without it, systems like water treatment plants and industrial setups would struggle to function effectively. Its design and material often determine the overall success of the application.

Understanding its mechanics is key to optimizing performance. This guide will explore its functions, types, and relevance in modern engineering. Stay tuned for an in-depth look at how this component shapes fluid handling systems.

Introduction to Pump Impellers

At the core of fluid handling systems lies a vital component that drives efficiency. This rotating part, often referred to as the 임펠러, is essential for converting mechanical energy into fluid motion. Its role in maintaining pressure and flow rates cannot be overstated.

The Importance in Fluid Dynamics

Fluid dynamics relies on the impeller to ensure smooth operation. As liquid enters the inlet, the rotating blades create centrifugal force, pushing it toward the discharge. This process is critical for maintaining consistent flow in systems like water treatment plants and industrial setups.

The design of the impeller plays a significant role in its efficiency. Properly engineered blades ensure minimal energy loss, maximizing performance. This makes it a cornerstone of modern engineering applications.

Overview of Pump Impeller Functionality

Understanding how impellers function is key to optimizing pump systems. They transfer energy from the motor to the fluid, ensuring smooth movement. This conversion process is vital for maintaining pressure and flow in various industrial applications.

From agricultural irrigation to marine systems, impellers are indispensable. Their ability to handle different fluids and conditions makes them versatile. This section sets the stage for a deeper dive into their design and applications in the following sections.

Design and Types of Pump Impellers

Different configurations of rotating parts cater to specific operational needs. The design of these components plays a crucial role in determining efficiency and reliability. Understanding the various types helps in selecting the right solution for fluid handling systems.

Open, Semi-Open, and Closed Impeller Designs

Open impellers feature vanes attached to a central hub without protective covers. They are ideal for handling liquids with suspended solids, offering easy maintenance. However, they may have lower efficiency due to fluid leakage.

Semi-open designs include a partial shroud on one side of the vanes. This provides better mechanical strength while still allowing solids to pass through. They strike a balance between performance and durability.

Closed impellers have vanes enclosed between two shrouds. This design minimizes fluid leakage, enhancing efficiency. They are best suited for clean liquids in high-pressure applications.

Vortex and Cutter Impellers Explained

Vortex impellers create a whirlpool effect, reducing clogging in systems handling solids or debris. They are commonly used in wastewater treatment and industrial processes. Their unique design ensures smooth operation even in challenging conditions.

Cutter impellers feature sharp blades designed to shred solids before they enter the system. This makes them ideal for applications like sewage treatment or agricultural irrigation. Their robust construction ensures long-term reliability.

| Type | Efficiency | NPSH | Maintenance |

|---|---|---|---|

| Open | Moderate | 낮은 | Easy |

| Semi-Open | 높은 | Moderate | Moderate |

| Closed | Very High | 높은 | Difficult |

| Vortex | Moderate | 낮은 | Easy |

| Cutter | 높은 | Moderate | Moderate |

Each type offers distinct advantages, making it essential to match the design to the application. Whether handling solids or clean liquids, the right choice ensures optimal performance and longevity.

Understanding What is a pump impeller

The efficiency of fluid systems depends heavily on the design and function of their core components. Among these, the 임펠러 stands out as a critical element. Its ability to convert mechanical energy into fluid motion ensures smooth operation across various applications.

Key Components and Energy Transfer Mechanisms

Every 임펠러 consists of several essential parts. The vanes are curved blades that generate centrifugal force, pushing fluid outward. The eye is the central opening where fluid enters, while the hub connects the impeller to the motor shaft.

Energy transfer begins when the motor rotates the impeller. As the vanes spin, they create centrifugal force, accelerating the fluid toward the discharge. This process ensures consistent flow and pressure in the system.

Several technical factors influence performance. These include the shape of the vanes, the size of the eye, and the material of the hub. Proper selection of these components is crucial for optimizing efficiency.

| Component | Function | Impact on Performance |

|---|---|---|

| Vanes | Generate centrifugal force | Determines flow rate |

| Eye | Allows fluid entry | Affects suction capacity |

| Hub | Connects to motor shaft | Ensures stability |

Understanding these components helps in making informed design choices. Whether for industrial or agricultural use, the right 임펠러 ensures reliable and efficient operation. Proper selection and design are key to achieving optimal results.

Impeller Diameter and Its Impact on Performance

The diameter of the rotating component significantly influences system outcomes. A larger size increases circumferential speed, enhancing both head and flow rate. This relationship is critical for achieving desired performance in fluid handling systems.

Effect on Flow Rate and Head

Increasing the diameter boosts the flow rate by accelerating fluid movement. It also raises the head, which is the height the liquid can be pumped. However, these changes must be balanced to avoid overloading the system.

예를 들어, a larger size may require more energy, reducing overall efficiency. Engineers often use pump curves to visualize these relationships and make informed decisions.

Optimizing Efficiency Through Impeller Trimming

Trimming involves reducing the diameter to meet specific process requirements. This practice can enhance efficiency by aligning the flow rate and head with operational needs. However, trimming should not exceed 75% of the original size to maintain system integrity.

Practical limits include effects on Net Positive Suction Head Required (NPSHr). Excessive trimming can lead to cavitation, damaging the system. Proper adjustments ensure optimal performance and longevity.

By balancing pressure 그리고 flow rate, engineers can achieve the best results. This approach is essential for maintaining efficiency in industrial and agricultural applications.

Materials and Construction Considerations

Material selection is a critical factor in ensuring the durability and efficiency of rotating components. The choice of material impacts wear, corrosion resistance, and overall performance. Different materials like stainless steel, bronze, and cast iron offer unique advantages and challenges.

Comparing Stainless Steel, Bronze, and Cast Iron

Stainless steel is known for its excellent corrosion resistance and strength. It is ideal for applications involving harsh chemicals or high temperatures. However, it can be more expensive, which may affect the overall cost of the system.

Bronze offers superior resistance to saltwater, making it a preferred choice for marine applications. It is also easier to machine, reducing construction challenges. Despite these benefits, bronze is less durable under high-stress conditions.

Cast iron is cost-effective and provides good mechanical strength. It is commonly used in industrial settings where budget constraints are a concern. However, it is prone to corrosion, requiring regular maintenance to prevent damage.

| Material | Corrosion Resistance | Strength | Cost | Maintenance |

|---|---|---|---|---|

| Stainless Steel | 높은 | 높은 | 높은 | 낮은 |

| Bronze | Moderate | Moderate | Moderate | Moderate |

| Cast Iron | 낮은 | 높은 | 낮은 | 높은 |

Material choices also influence the design of the pump’s case. 예를 들어, stainless steel cases are often used in high-pressure systems to ensure mechanical strength. Bronze cases are preferred in marine environments to prevent corrosion. Cast iron cases are common in industrial applications due to their cost-effectiveness.

Proper maintenance is essential to prevent damage and ensure long-term performance. Regular inspections can identify wear and tear early, reducing the risk of system failure. Selecting the right material based on operating conditions can minimize maintenance requirements and enhance reliability.

Application Areas and Industry Use-Cases

Impeller pumps are integral to fluid transfer systems, driving efficiency across diverse industries. Their design and functionality make them essential for various applications, from industrial setups to agricultural and marine operations. Understanding their use in different systems helps optimize performance and reliability.

Centrifugal, Axial, and Mixed-Flow Pump Systems

In centrifugal pump systems, impellers generate centrifugal force to move fluids. These are widely used in water treatment plants and irrigation due to their high efficiency and ability to handle large volumes. Axial systems, on the other hand, use propeller-like impellers to push fluids parallel to the shaft, ideal for low-pressure, high-flow applications like flood control.

Mixed-flow systems combine features of both, offering a balance between pressure and flow. They are commonly used in industrial cooling processes and wastewater management. Each system has unique requirements, influencing the choice of impeller design for optimal performance.

Industrial, Agricultural, and Marine Applications

In industrial settings, impeller pumps are crucial for processes like chemical transfer and cooling. Their ability to handle corrosive fluids and high temperatures makes them indispensable. 예를 들어, stainless steel impellers are often used in chemical plants to ensure durability and reliability.

Agricultural applications rely on these pumps for irrigation and water distribution. Open impellers are preferred for handling water with suspended solids, ensuring smooth operation in challenging conditions. Marine systems use bronze impellers to resist saltwater corrosion, maintaining efficiency in harsh environments.

Proper impeller design ensures these systems meet specific process requirements. Factors like fluid characteristics and environmental demands guide engineering choices, ensuring long-term reliability and performance.

Optimizing Pump Performance and Efficiency

Effective fluid handling relies on optimizing key components for peak performance. Proper care and strategic choices ensure systems operate smoothly while minimizing energy consumption. This section explores actionable steps to enhance reliability and reduce operational costs.

Maintenance Tips for Longevity and Reliability

Regular upkeep is essential for maintaining system integrity. Cleaning, inspection, and lubrication are critical tasks that prevent wear and tear. 예를 들어, removing debris from the impeller ensures consistent performance and reduces strain on the motor.

Common mistakes include neglecting lubrication or ignoring early signs of damage. Addressing these issues promptly extends the lifespan of the system. Facility managers should establish a routine schedule to monitor and address potential problems.

Energy Savings Through Proper Impeller Selection

Choosing the right design significantly impacts energy consumption. A well-matched impeller ensures optimal efficiency, reducing operational costs. 예를 들어, selecting a closed impeller for clean liquids minimizes energy loss compared to open designs.

Excessive trimming can lead to efficiency losses. Engineers should follow best practices, such as limiting trimming to 75% of the original size. This approach maintains system balance and prevents cavitation.

| Maintenance Task | Frequency | Impact on Performance |

|---|---|---|

| Cleaning | Monthly | Prevents clogging |

| Inspection | Quarterly | Identifies wear early |

| Lubrication | Bi-annually | Reduces friction |

Monitoring system feedback allows for timely adjustments. Regularly reviewing performance metrics ensures the system operates at its best. These practices not only enhance efficiency but also contribute to long-term reliability.

Troubleshooting Common Pump Impeller Issues

Ensuring smooth operation in fluid systems often requires addressing potential issues with the rotating components. Common problems like wear, contact with solids, and improper clearance can disrupt performance. Proactive troubleshooting is essential to minimize downtime and maintain efficiency.

Identifying and Preventing Impeller Damage

Damage to the rotating parts can stem from several factors. Wear over time, contact with abrasive solids, and incorrect clearance are frequent culprits. Regular inspections help identify these issues early, preventing costly repairs.

Vibration and misalignment are additional factors that contribute to damage. Excessive vibration can weaken components, while misalignment increases stress on the system. Addressing these issues promptly ensures long-term reliability.

Preventive measures include proper installation techniques and routine maintenance. 예를 들어, ensuring adequate clearance and alignment reduces wear. Regular cleaning prevents buildup that could impair performance.

Real-life examples highlight the impact of damage on system efficiency. In industrial setups, unresolved issues can lead to significant downtime and repair costs. Addressing problems promptly maintains optimal process performance.

By following these strategies, operators can minimize downtime and extend the lifespan of their systems. Proactive troubleshooting and preventive care are key to ensuring smooth and efficient operations.

결론

Selecting the right components ensures fluid systems operate at their best. The 임펠러 plays a critical role in energy transfer, directly impacting system efficiency. Different designs, from open to closed configurations, cater to specific requirements, ensuring optimal performance.

Diameter and material choices also influence outcomes. Larger sizes enhance flow rate, while materials like stainless steel or bronze address durability and corrosion concerns. Regular maintenance further extends system lifespan, reducing downtime and repair costs.

When making a choice, consider technical specifications and real-life examples. Consulting professionals ensures the right fit for your requirements. Proper selection and care lead to superior results, 만들기 임펠러 a cornerstone of efficient fluid handling.

For expert guidance or further research, explore advanced pump technology. The right choice ensures your system achieves peak performance and reliability.