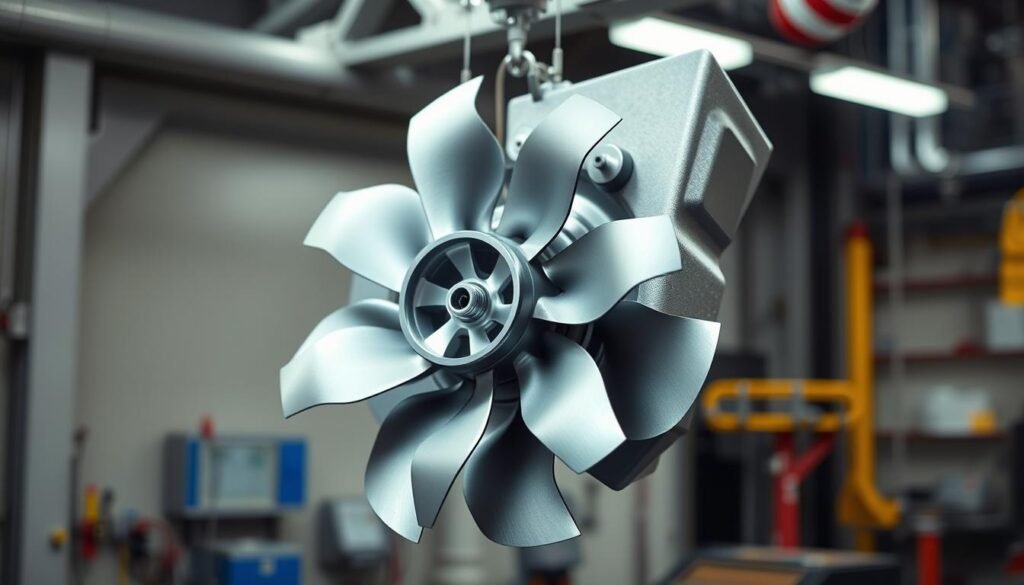

The process of making automotive turbocharger impellers is very complex. It needs a lot of knowledge in materials science, mechanical engineering, and advanced manufacturing. This process makes impellers strong enough to handle high temperatures, pressures, and speeds. It’s key for turbochargers to work well.

Creating high-quality turbocharger impellers is crucial for modern car engineering. It ensures the impellers can handle the tough demands of today’s cars.

Precision manufacturing is key in making turbocharger impellers for cars. It helps create parts that boost engine performance. By using the latest in manufacturing and materials science, makers can meet the high standards of the car industry. 여기, precision and design are very important.

Understanding Automotive Turbocharger Impellers

Automotive turbocharger impellers are key in making engines better. They help engines work more efficiently and powerfully. The 임펠러 제조 process creates these parts, which push air into the engine’s chamber. This boosts power and cuts down on fuel use, vital for today’s cars.

The main parts of a turbocharger impeller are the compressor wheel, turbine wheel, and shaft. Together, they compress air for the engine. Making these parts right is crucial for their performance and efficiency.

Important things to think about when making turbocharger impellers include:

- 재료 선택: The material used affects how well the impeller works and lasts.

- Aerodynamic design: The compressor and turbine wheels need to be shaped right for air to flow well.

- Structural integrity: The impeller must handle the engine’s stresses and loads.

Knowing about turbocharger impellers helps makers improve their 임펠러 제조. This leads to better, more efficient parts for modern automotive engineering.

Materials Used in Modern Impeller Production

Choosing the right materials for turbocharger impellers is key. It impacts their performance, durability, and reliability. Materials science is vital in this area. It helps us understand different materials and their uses. Today, we use advanced materials like titanium alloys, nickel-based superalloys, and ceramic composites.

These materials are strong yet light. They resist corrosion and fatigue well. They can also handle very high temperatures. Some important features of these materials are:

- High thermal resistance

- Corrosion resistance

- High strength-to-weight ratio

Studies and reports on materials science 그리고 advanced materials show their benefits. Using these materials has made turbochargers work better and more efficiently. The need for better turbochargers is driving the use of advanced materials even more.

Advanced Manufacturing Techniques for Turbocharger Impellers

Making turbocharger impellers needs special manufacturing methods. These methods help create complex shapes and exact sizes. Computer-aided design (CAD) is key here. It lets makers design and test their ideas before making them real.

CNC machining is also vital for making these impellers. It uses computers to control machines that shape the impeller parts. This makes the impeller very precise and smooth, which is crucial for its performance.

Key Manufacturing Techniques

- Computer-aided design (CAD) for detailed design and simulation

- CNC machining for precise cutting and shaping

- Surface finishing techniques, such as grinding and polishing, for a smooth surface finish

Using these advanced techniques, makers can create top-notch turbocharger impellers. These impellers meet high standards for performance, efficiency, and durability. CNC machining and CAD help make complex shapes and exact sizes, leading to better performance.

Quality Control Standards in Impeller Manufacturing

Quality control is key in making turbocharger impellers. It affects how well they work, how reliable they are, and if they’re safe. Companies must follow strict quality control standards and rules. These come from groups like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM).

To stick to standards compliance, makers use many quality control steps. These include:

- Checking materials and parts often

- Keeping equipment in top shape

- Training and certifying workers

These steps help make sure turbocharger impellers are up to par. They lead to better performance, reliability, and safety.

Quality control is not just about meeting standards, but also about continuously improving processes and procedures to ensure the highest level of quality and reliability.

Precision Testing Methods for Automotive Turbocharger Impellers

To make sure turbocharger impellers work well, we need precise testing. These tests check if the impeller is reliable and efficient. They also make sure it runs smoothly by balancing it.

Testing how the impeller performs is key. It sees how it handles different pressures and temperatures. This helps fix any problems and improve its design.

It’s also important to check how long the impeller lasts. This means testing its strength against wear and tear. Doing this ensures it can handle being used over and over again.

- Simulating real-world conditions to evaluate the impeller’s performance

- Conducting balancing procedures to minimize vibration

- Evaluating the impeller’s resistance to fatigue and corrosion

Using performance testing 그리고 durability assessment makes sure impellers are top-notch. This boosts the car’s performance and efficiency.

Innovation in Impeller Design and Production

The world of turbocharger impeller design and production is always changing. This change comes from innovation 그리고 research and development. Companies are using new technologies to make things better. They focus on using advanced materials and new ways to make things, like 3D printing.

New materials and ways to make things can change the game. 예를 들어, research and development in computational fluid dynamics has improved. Now, designers can use better tools to make impellers work better and need fewer prototypes.

As things keep moving forward, we’ll see even more new ideas. Future research and development might include adding advanced sensors and making manufacturing greener. By being open to innovation and investing in research and development, companies can lead the way in the turbocharger impeller market.

Industry Applications and Performance Metrics

Turbocharger impellers are used in many fields, like cars, racing, and trucks. Each area needs different things, like power, fuel use, and how long they last. Now, more people want turbocharger impellers that work better and last longer for cars.

These impellers are used in many places, from cars to trucks and racing cars. What they need to do changes, like more power or better fuel use. Reports say there’s a big push for turbocharger impellers that are more efficient and last longer for cars.

Automotive Sector Requirements

Cars need turbocharger impellers that are powerful, use less fuel, and last a long time. The push for cleaner, more efficient cars has made people want better turbocharger impellers. Key things cars need from these impellers are:

- Power output: The turbocharger impeller should make the engine stronger.

- Fuel efficiency: It should help the engine use less fuel.

- Durability: It must handle the engine’s tough conditions well.

Racing and High-Performance Applications

Racing and high-performance cars need turbocharger impellers that are very powerful and can handle extreme conditions. What’s important for these cars is:

- High power output: The turbocharger impeller should make the engine very strong.

- Lightweight design: It should be light to help the engine move faster.

- High durability: It must be able to handle the tough racing environment.

| Application | Power Output | Fuel Efficiency | Durability |

|---|---|---|---|

| Automotive Sector | 높은 | 높은 | 높은 |

| Racing and High-Performance | Very High | 중간 | Very High |

| Commercial Vehicles | 중간 | 높은 | 높은 |

결론: The Future of Turbocharger Impeller Manufacturing

The future of turbocharger impeller manufacturing looks bright. New technologies like additive manufacturing 그리고 advanced materials will change the game. Additive manufacturing, or 3D printing, can create complex designs. Advanced materials, like lightweight composites, will boost performance and efficiency.

The industry is also becoming more digital. This change will transform how impellers are made and tested. New tools for simulation and data analysis will help improve quality and performance.

The automotive world needs better turbochargers, and impeller manufacturing is ready to answer. By embracing new technologies, makers can meet the market’s needs. This ensures their products meet the high standards of car lovers and users.