Choosing the right technology for impeller surface wear repair is key. Laser cladding and thermal spraying are two top choices. Laser cladding is known for its precision, making it great for repairing impeller surfaces. Thermal spraying, on the other hand, is more affordable and offers many material options.

Deciding between laser cladding and thermal spraying is important for keeping equipment running well. This article will compare both, highlighting their good points and bad. We aim to help you make a smart choice.

Looking into laser cladding and thermal spraying helps us see their strengths and weaknesses. We’ll dive into the benefits and drawbacks of each. Knowing the differences is vital for fixing damaged impellers or preventing future wear.

Understanding Impeller Surface Wear and Its Impact on Performance

Impeller repair is key to keeping equipment running well. It tackles surface wear caused by corrosion, erosion, and abrasion. These factors can really hurt how well the equipment works.

It’s important to check the equipment regularly. Look for signs like more vibration, noise, and heat. Early detection can stop bigger problems and save money on repairs.

Common Causes of Impeller Wear

- Corrosion: Chemical reactions between the impeller material and the surrounding environment

- Erosion: Wear caused by the flow of fluids or gases

- Abrasion: Wear caused by the contact between the impeller and other surfaces

Effects on Equipment Efficiency

Wear on the impeller can make equipment less efficient. This means less work done and more energy used.

Critical Signs of Surface Degradation

| Sign | Description |

|---|---|

| Increased Vibration | Excessive vibration can indicate imbalance or wear on the impeller |

| Noise | Unusual noises can indicate surface wear or other issues with the equipment |

| Temperature Increase | Increased temperature can indicate reduced equipment efficiency and surface wear |

Fixing surface wear through impeller repair keeps equipment running smoothly. Knowing what causes wear and spotting signs early helps. 이런 식으로, equipment lasts longer and works better.

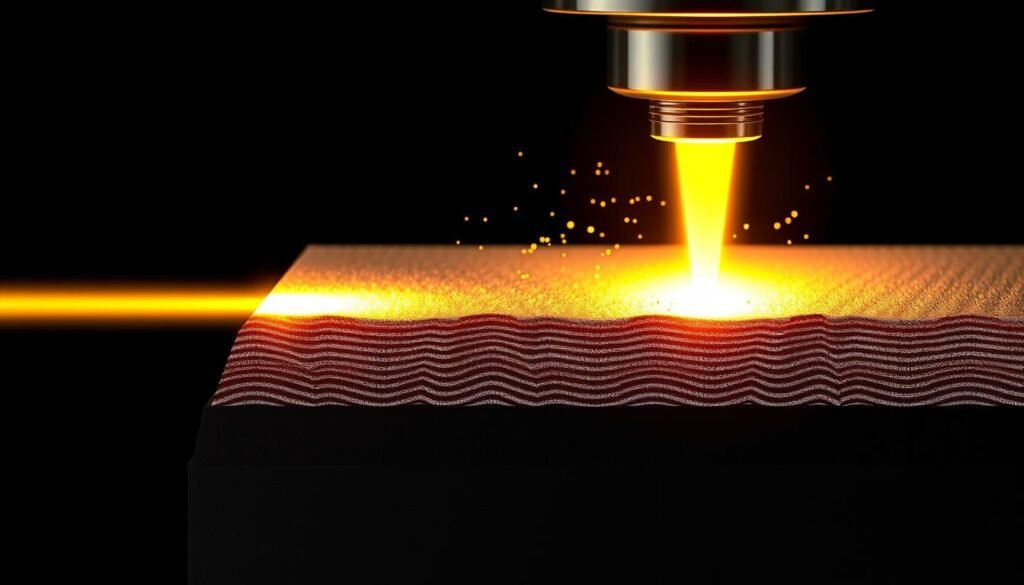

The Science Behind Laser Cladding Technology

Laser cladding is a method for fixing surfaces. It uses a strong laser to melt and join material to a base. This tech is popular because it creates a strong bond, perfect for repairs and coatings.

The process starts with a laser, powders or wires, and a base. The laser melts the powder or wire, which then sticks to the base. This bond is strong and doesn’t mess up the nearby material. Laser cladding is great for fixing tricky shapes and for coating delicate parts.

Some key benefits of laser cladding are:

- High precision and control over the cladding process

- Ability to deposit a wide range of materials, including metals and ceramics

- Minimal heat input, reducing the risk of distortion or damage to the substrate

Laser cladding technology is used for surface repair and coating. It’s used in aerospace, automotive, and energy fields. Knowing how laser cladding works helps manufacturers and engineers make their equipment better and last longer.

Thermal Spraying Process and Applications

Thermal spraying is a method to coat surfaces by spraying molten particles. It’s used in aerospace, automotive, and healthcare. This is because it creates a strong, durable, and corrosion-resistant coating.

The process uses different spray methods like plasma, flame, and arc spraying. Each method has its own benefits and drawbacks. The right method depends on the specific needs of the application.

Different Types of Thermal Spray Methods

- Plasma spraying: uses a high-temperature plasma arc to melt and propel particles

- Flame spraying: uses a flame to melt and propel particles

- Arc spraying: uses an electric arc to melt and propel particles

Material Selection Considerations

Choosing the right material for thermal spraying is key. Metals, ceramics, and polymers are common choices. The material must match the application’s needs, such as corrosion resistance and wear.

| Material | Properties | Applications |

|---|---|---|

| Metal | High strength, corrosion resistance | Aerospace, automotive |

| Ceramic | High hardness, wear resistance | Healthcare, industrial |

| Polymer | Low friction, corrosion resistance | Automotive, industrial |

Impeller Surface Wear Repair: Comparative Analysis of Both Technologies

Impeller repair is all about fixing surface wear. Laser cladding and thermal spraying are two main methods. Each has its own strengths and weaknesses.

Laser cladding creates a strong bond with the impeller. This is because the laser beam has high energy. Thermal spraying, on the other hand, has a mechanical bond that’s not as strong.

Bond Strength and Durability

- Laser cladding: strong metallurgical bond

- Thermal spraying: mechanical bond

Surface finish is also key. Laser cladding makes the surface smooth. Thermal spraying can leave it rougher.

Surface Finish Quality

Choosing between laser cladding and thermal spraying depends on the repair needs. Engineers look at bond strength, surface finish, and how heat affects the area. This helps pick the best method for the job.

| Technology | Bond Strength | Surface Finish Quality |

|---|---|---|

| Laser Cladding | Strong metallurgical bond | Smooth, even surface |

| Thermal Spraying | Mechanical bond | Rough surface |

Cost-Benefit Analysis and ROI Considerations

When deciding on impeller repair, a detailed cost-benefit analysis is key. Cost-benefit analysis looks at the costs of each repair method. This includes equipment, 재료, and labor. It also compares these costs to the benefits. In impeller repair, ROI considerations are vital. They help figure out the return on investment for each method.

Choosing the right repair method is a big part of the analysis. 예를 들어, laser cladding and thermal spraying have different costs. Here are some things to think about:

- Equipment costs: Laser cladding equipment is pricier than thermal spraying’s.

- Material costs: Laser cladding materials are often cheaper than thermal spraying’s.

- Labor costs: Laser cladding labor is usually more expensive than thermal spraying’s.

Laser cladding might seem pricey, but it has big benefits. It boosts efficiency, cuts downtime, and extends equipment life. Impeller repair with laser cladding can save a lot of money in the long run. It’s a good choice for companies wanting to reduce downtime and increase productivity. Here’s a table comparing laser cladding and thermal spraying:

| Repair Method | Equipment Cost | Material Cost | Labor Cost | Benefit |

|---|---|---|---|---|

| Laser Cladding | 높은 | 낮은 | 높은 | Increased efficiency, reduced downtime, extended equipment life |

| Thermal Spraying | 낮은 | 높은 | 낮은 | Reduced equipment cost, faster repair time |

결론: Making the Right Choice for Your Impeller Repair Needs

Choosing between laser cladding and thermal spraying for impeller repair depends on your needs. Each technology has its own strengths. You need to think about what your equipment needs and what you want to achieve.

Laser cladding is great for its strong bond and smooth finish. It’s perfect for situations where durability and precision matter a lot. Thermal spraying, while less expensive, is more versatile. It suits many needs well.

When picking the right repair method, think about bond strength, surface finish, and cost. This article has covered these important points. Making a smart choice will help your equipment last longer and work better. This will help your business succeed.

New advancements in laser cladding and thermal spraying are promising. They could lead to even better repair solutions in the future. Keep up with these advancements. Choose the best option for your specific needs.