Accurate impeller pitch measurement is essential for optimizing waterjet performance. Whether you’re a professional or an enthusiast, understanding this process ensures better RPM, acceleration, and overall thrust. This guide provides detailed insights to help you achieve precise results.

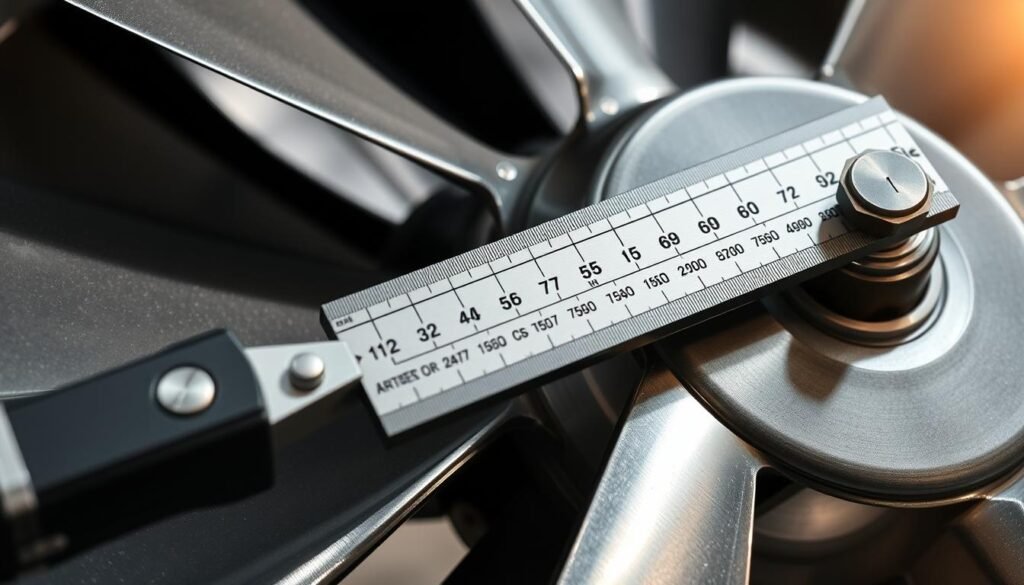

Based on expert advice from John Zigler of Watercraft Talk, this article highlights the use of specialized tools like Watcon Impeller Pitch Ring Gauges. These gauges, available in sizes from 140mm to 171mm, are designed for accuracy and ease of use.

Upcoming sections will cover definitions, step-by-step instructions, and tool selection. This guide is tailored for readers in the United States, offering practical examples and technical insights to enhance your understanding.

Overview of Impeller Pitch and Its Impact

The pitch of an impeller plays a critical role in determining waterjet performance. It refers to the angle of the blades, which dictates how water is displaced and thrust is generated. Understanding this concept is essential for optimizing your watercraft’s efficiency.

Definition and Importance of Impeller Pitch

Impeller pitch is the angle at which the blades are set to move water through the propulsion system. A lower pitch increases RPM, making it ideal for quick acceleration. A higher pitch, on the other hand, emphasizes top-end speed. Accurate measurement ensures the right balance for your specific needs.

Effects on RPM, Acceleration, and Performance

Changes in pitch directly impact engine performance. A lower pitch allows for faster RPM, which is crucial for quick starts. A higher pitch provides better thrust at higher speeds. Progressive pitch designs offer a blend of both, enhancing initial hook-up and maintaining efficiency at top speeds.

Selecting the correct gauge size is vital for precise measurements. The right size ensures compatibility with your impeller design, leading to accurate adjustments and improved performance. Understanding these factors helps in making informed decisions when choosing replacement impellers.

How to measure impeller pitch

Ensuring precise blade angle alignment is key to maximizing watercraft efficiency. Proper calibration ensures optimal thrust, RPM, and acceleration. This section outlines a detailed process to achieve accurate results.

Step-by-Step Alignment Process

Begin by positioning the impeller on a stable surface. Align the Watcon gauge with the marked lines on the blade. Focus on the first inch, where deviations often start. This step is critical for progressive pitch designs.

Secure the gauge firmly against the blade. Ensure it fits snugly to avoid misalignment. Double-check the position to confirm accuracy. Consistent alignment guarantees reliable readings.

Using Gauges for Reliable Results

Specialized gauges like the Watcon Pitch Ring are essential for precision. They account for differences between leading and trailing edges. Choose a gauge that matches the impeller’s size for consistent measurements.

Misalignment or incorrect gauge selection can lead to errors. Always verify the gauge’s fit before taking readings. Precise calibration ensures optimal performance and extends engine lifespan.

Selecting Tools and Techniques for Precision Measurements

Precision tools are critical for achieving accurate blade angle readings. Specialized gauges, like the Watcon Impeller Pitch Ring, ensure reliable results. These tools are available in four sizes, ranging from 140mm to 171mm, catering to various designs.

Overview of Impeller Pitch Ring Gauges

Watcon gauges are designed for both leading and trailing edge measurements. Their precision ensures compatibility with different blade designs. Using the correct size is essential for accurate readings and optimal performance.

Common sizes include 140mm, 155mm, 165mm, and 171mm. Each gauge is crafted to fit snugly against the blade, minimizing errors. Proper selection avoids inconsistencies, especially with specific impeller brands.

Understanding Leading vs. Trailing Edge Measurements

Measurements at the leading edge impact acceleration and bottom-end hook-up. The first inch from this edge is particularly vital for progressive designs. Accurate readings here ensure better initial performance.

Trailing edge measurements correlate with top speed and pump pressure. Balancing both edges is key to achieving optimal thrust and efficiency. The table below highlights the differences:

| Measurement Type | Impact on Performance |

|---|---|

| Leading Edge | Affects acceleration and bottom-end hook-up |

| Trailing Edge | Influences top speed and pump pressure |

For professionals and DIY enthusiasts, selecting the right tool is crucial. Regular maintenance ensures long-term accuracy. Industry standards recommend verifying gauge fit before each use.

Conclusion

Proper blade angle alignment ensures optimal watercraft performance. Accurate calibration directly impacts thrust, speed, and engine efficiency. Using high-quality tools like the Watcon Impeller Pitch Gauge is essential for reliable results.

Following detailed instructions guarantees precise readings. This not only enhances performance but also extends engine longevity. Regular monitoring of blade angles is a key step in maintaining peak efficiency.

Apply the techniques and insights shared in this guide for consistent, accurate results. For further optimization, explore related topics in marine propulsion adjustments. Always verify measurements with trusted tools to ensure precision.