Der Laufrad serves as the heart of a centrifugal pump, driving the movement of Flüssigkeit through the system. Das rotating component transfers energy from the motor to the liquid, increasing pressure and ensuring steady fließen. Its design, including the number and shape of Klingen, directly impacts the pump’s efficiency und Leistung.

Located within the pump casing, the impeller draws Flüssigkeit durch die inlet and propels it outward using centrifugal force. This process is essential in applications ranging from industrial water treatment to agricultural irrigation. Understanding the impeller’s function is the first step in optimizing pump performance and ensuring reliable operation across various sectors.

Impeller Designs and Their Impact on Pump Performance

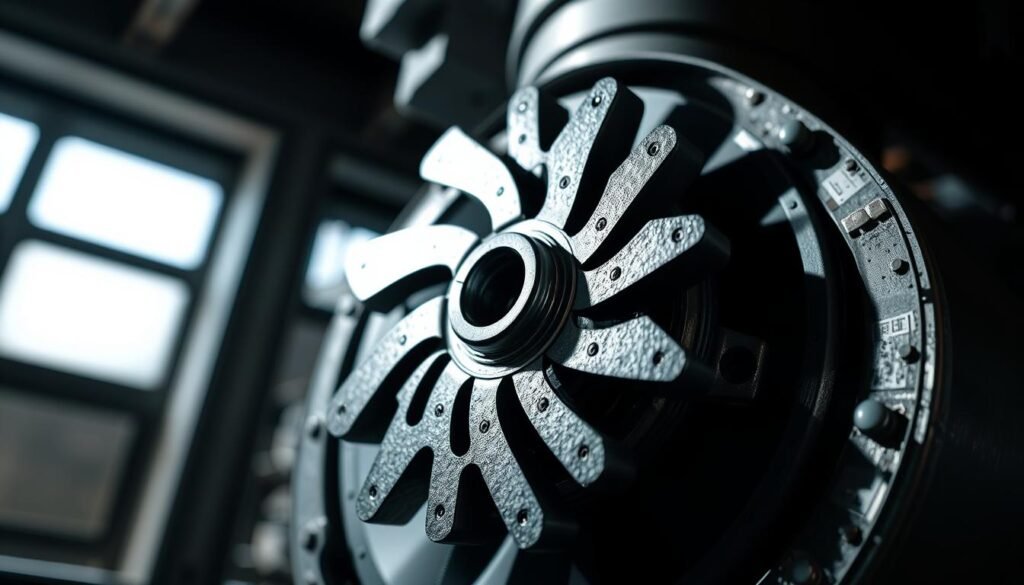

Impeller designs play a critical role in determining pump efficiency and functionality. The choice of impeller type directly affects pressure, fließen, and energy transfer within the system. Understanding the differences between various designs helps in selecting the right pump for specific applications.

Exploring Open, Semi-Open, and Closed Impellers

Open impellers feature exposed vanes, making them ideal for handling fluids with suspended solids. Their simple design allows for easy maintenance, but they are less efficient compared to other types. These impellers are commonly used in wastewater treatment and industrial applications.

Semi-open impellers strike a balance between strength and flexibility. They have a single shroud on one side, providing better efficiency than open designs while still handling medium-sized solids. This makes them suitable for applications like agricultural irrigation and chemical processing.

Closed impellers are enclosed by shrouds on both sides, offering higher efficiency and lower NPSH requirements. They are ideal for clean liquids and high-pressure systems, such as those in HVAC and water supply networks. Jedoch, they are more complex to maintain.

Understanding Vortex and Cutter Impeller Concepts

Vortex impellers create a whirlpool effect, isolating debris from the impeller itself. This design minimizes clogging and wear, making it perfect for handling sludge and other abrasive materials. They are widely used in sewage and wastewater treatment plants.

Cutter impellers are designed to grind solids into smaller particles, preventing blockages in the pump. These impellers are essential in applications like municipal sewage systems, where large solids are common. Their robust construction ensures long-lasting performance in demanding environments.

Each impeller design has unique advantages, influencing factors like pressure, flow rate, and energy consumption. By selecting the appropriate type, users can optimize pump performance for their specific needs.

What is an impeller on a pump

At the core of every centrifugal pump lies a critical component that drives fluid movement. This rotating part, often referred to as the Laufrad, transfers energy from the motor to the liquid, creating pressure and ensuring steady flow. Its design, including the number and shape of vanes, directly impacts the pump’s efficiency and performance.

The Role of the Impeller in Fluid Transfer Systems

The impeller is the heart of a pump system, responsible for generating centrifugal force. As it spins, it draws fluid through the inlet and propels it outward, creating both suction and discharge. This two-part process is essential for moving liquids in applications ranging from water treatment to industrial processes.

The design of the impeller, particularly its vanes and inlet eye, plays a crucial role in determining flow rate and pressure. Zum Beispiel, a larger impeller diameter increases head and flow rate, while the vane configuration influences energy transfer efficiency. Proper clearances within the pump casing are also vital for optimal performance.

Motor power and impeller speed are directly linked to liquid movement. Higher speeds generate greater centrifugal force, increasing pressure and flow. Jedoch, balancing these factors is key to achieving energy efficiency and preventing system wear.

| Impeller Type | Key Features | Applications |

|---|---|---|

| Offener Laufrad | Exposed vanes, easy maintenance | Wastewater treatment, industrial use |

| Semi-offener Laufrad | Single shroud, handles medium solids | Agricultural irrigation, Chemische Verarbeitung |

| Geschlossenes Laufrad | Enclosed by shrouds, high efficiency | HVAC, water supply networks |

Different impeller designs are tailored to specific applications. Zum Beispiel, open impellers handle suspended solids, while closed impellers are ideal for clean liquids. Selecting the right type ensures optimal pump performance and longevity.

Applications, Innovations, and Maintenance of Pump Impellers

From industrial plants to agricultural fields, impellers play a pivotal role in fluid handling. Their design and functionality are tailored to meet the demands of various applications, ensuring efficient operation across diverse sectors. Whether it’s water treatment, irrigation, or marine systems, the right impeller choice can significantly enhance performance.

Industrial, Agricultural, and Marine Applications

In industrial settings, impellers are crucial for processes like chemical processing and wastewater treatment. Open impellers handle suspended solids effectively, while closed designs are preferred for clean liquids in HVAC systems. These components ensure consistent flow and pressure, critical for maintaining operational efficiency.

Agricultural applications rely on impellers for irrigation and water distribution. Semi-open designs are ideal for handling medium-sized solids, ensuring reliable performance in challenging environments. Their durability and efficiency make them a staple in modern farming operations.

Marine systems benefit from impellers designed to withstand corrosive environments. Vortex impellers, for instance, minimize clogging in shipboard wastewater systems. Their ability to handle abrasive materials ensures long-lasting performance in demanding conditions.

Maintenance Strategies and Performance Optimization

Regular maintenance is essential for maximizing impeller lifespan and efficiency. Cleaning debris from vanes and adjusting wear-ring clearances can prevent performance degradation. Routine inspections help identify wear and tear early, reducing downtime and repair costs.

Innovative trimming techniques allow impellers to match specific duty points, optimizing energy consumption. Upgrades like reinforced materials or advanced coatings can enhance durability in harsh environments. These strategies not only improve efficiency but also lower operational costs.

| Maintenance Task | Benefit | Frequency |

|---|---|---|

| Cleaning Vanes | Prevents clogging and maintains flow rate | Monthly |

| Wear-Ring Adjustment | Ensures optimal clearances for efficiency | Quarterly |

| Inspection of Blades | Identifies wear and prevents system failure | Bi-Annually |

Proper impeller selection and maintenance are key to achieving long-term reliability. By understanding the specific needs of each application, users can optimize performance and extend the life of their pump systems.

Abschluss

Efficient Flüssigkeit transfer relies heavily on the right Laufrad selection. As the core component of a Pumpe, Die Laufrad directly impacts pressure, fließen, and energy efficiency. Choosing between open, semi-open, and closed designs ensures optimal performance for specific applications.

Proper maintenance routines, such as cleaning vanes and adjusting wear rings, enhance longevity and reduce operational costs. Aligning Laufrad type with application needs, whether in water treatment or industrial processes, maximizes efficiency and reliability.

Understanding design factors like vane configuration and pump casing fit is essential. By prioritizing these elements, users can achieve long-lasting, efficient Pumpe operation and minimize downtime.