In mechanical systems, determining the rotational velocity of an impeller is essential for optimal performance. This value directly impacts efficiency, especially in applications like pumps and superchargers. By understanding this metric, engineers can ensure systems operate smoothly and effectively.

One key aspect is Spitzengeschwindigkeit, which measures the speed at the outer edge of the impeller. It’s calculated using the formula: TS = π × D × RPM / 60. This equation helps professionals evaluate performance and make necessary adjustments.

To simplify this process, online tools are widely used. These calculators allow users to input values like diameter and RPM, providing quick and accurate results. This eliminates manual errors and saves time, making it a preferred choice for many engineers.

This article will explore the formula in detail, provide step-by-step examples, and discuss practical applications. Whether you’re working with pumps or superchargers, understanding this concept ensures precision and reliability in your projects.

Understanding Impeller Mechanics and Tip Speed

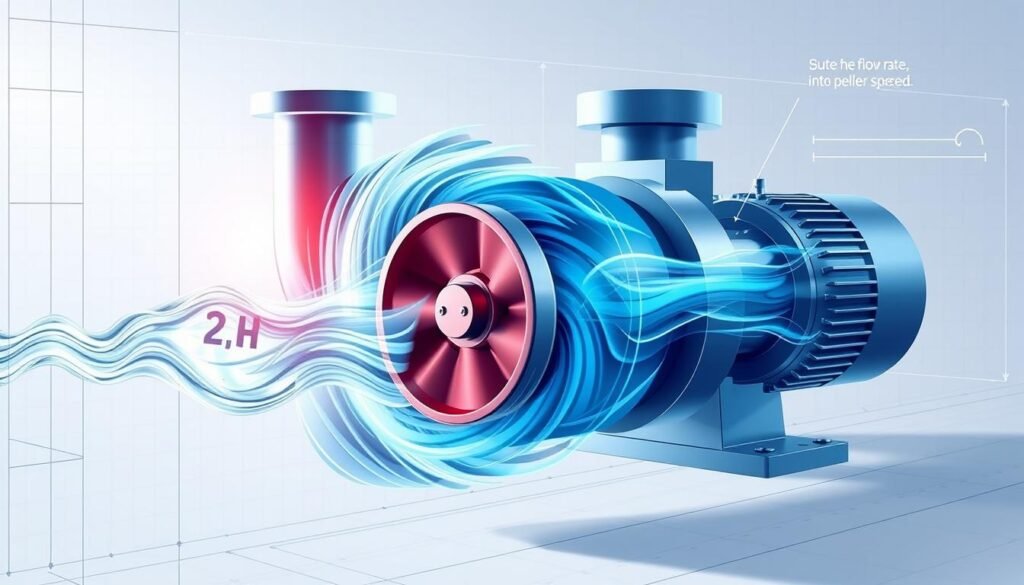

The mechanics of an impeller play a pivotal role in fluid dynamics and system efficiency. This rotating component is essential in centrifugal pumps, compressors, and superchargers, driving fluid movement and pressure. Its design directly impacts the performance of these systems, making it a critical element in mechanical engineering.

Definition and Function of an Impeller

An Laufrad is the rotating part of a centrifugal system that transfers energy to the fluid. It consists of blades or vanes that spin, creating a force that moves the fluid. In automotive applications, impellers are used in superchargers to increase air intake, boosting engine power. In industrial settings, they are integral to pumps that move liquids like water or chemicals.

What is Tip Speed?

Tip speed refers to the tangential velocity at the outer edge of the impeller. It’s a crucial metric for evaluating performance, as it determines how efficiently the impeller moves fluid. Higher tip speeds can increase output but may also lead to wear and tear. Engineers often balance this factor to optimize system longevity and efficiency.

The design of an impeller, including the number of blades and their angle, influences its operational characteristics. Zum Beispiel, a higher blade angle can increase fluid flow but may require more energy. Understanding these design elements helps professionals tailor systems for specific applications, ensuring both reliability and performance.

How to calculate impeller speed: A Step-by-Step Calculation Guide

Understanding the rotational dynamics of an impeller is crucial for system efficiency. This section provides a step-by-step guide to determining its speed, ensuring precision in mechanical applications. By mastering these calculations, engineers can optimize performance and reduce errors.

Formula Breakdown and Explanation

The tip speed formula, TS = π × D × RPM / 60, is fundamental for evaluating impeller performance. Each component plays a specific role:

| Component | Beschreibung |

|---|---|

| au (Pi) | A mathematical constant (~3.1416) used in circular calculations. |

| D (Durchmesser) | The width of the impeller, measured in feet or meters. |

| Drehzahl | Revolutions per minute, indicating how fast the impeller rotates. |

| 60 | Converts RPM to revolutions per second for accurate speed measurement. |

This formula ensures engineers can evaluate the tangential velocity at the impeller’s outer edge, a critical metric for system efficiency.

Example Problem Walkthrough

Consider an impeller with a 1.25-foot diameter rotating at 100 Drehzahl. Applying the formula:

TS = π × 1.25 × 100 / 60 = 6.544 ft/s.

This result indicates the tip speed, helping engineers assess performance and make necessary adjustments. Such calculations are vital for maintaining system reliability.

Utilizing the Speed Calculator Effectively

Online speed calculators simplify these calculations, reducing manual errors and saving time. By inputting values like diameter and RPM, users receive instant, accurate results. This tool is invaluable for both students and professionals, ensuring precision in every project.

Practical Applications in Pump and Supercharger Systems

Accurate impeller speed calculations are vital for optimizing pump and supercharger systems. These systems rely on precise measurements to ensure efficiency, reliability, und Leistung. Whether in automotive or industrial settings, understanding the dynamics of impeller speed is essential for achieving desired outcomes.

Real-World Calculator Interfaces and Tools

Online calculators have revolutionized the way professionals determine impeller speed. Tools like the V-2/V-3 and V-1/V-7 supercharger calculators allow users to input variables such as diameter and RPM, delivering instant results. These interfaces are user-friendly, reducing the risk of manual errors and saving valuable time.

Zum Beispiel, the V-2/V-3 calculator is widely used in automotive applications to fine-tune supercharger performance. Similarly, the V-1/V-7 tool is favored in industrial settings for optimizing pump systems. Choosing the right calculator depends on system requirements and the specific application.

Comparing Impeller and Pump Configurations

Impeller designs vary significantly between pumps and superchargers. In Pumpe systems, impellers are optimized for fluid movement, often featuring curved blades to enhance flow efficiency. Superchargers, auf der anderen Seite, prioritize air compression, requiring impellers with steeper blade angles for increased pressure.

These design differences impact performance and maintenance. Zum Beispiel, higher Tipp speeds in superchargers can lead to increased wear, necessitating frequent inspections. In contrast, pump impellers are designed for durability, ensuring long-term operation in demanding environments.

Understanding these configurations helps engineers select the right impeller for their needs, balancing efficiency and longevity.

Practical applications of these principles are evident in industries like automotive and manufacturing. In automotive systems, precise impeller speed ensures optimal engine performance. In manufacturing, accurate calculations maintain the efficiency of industrial pumps, reducing downtime and operational costs.

Advanced Concepts: Flow Rate and System Efficiency

Flow rate and system efficiency are critical factors in centrifugal pump performance. These elements determine how effectively a pump moves fluid, impacting energy consumption and operational costs. Understanding the relationship between impeller speed, Durchmesser, and flow rate is essential for optimizing these systems.

Link Between Impeller Speed and Flow Rate

The flow rate in a centrifugal pump is directly influenced by the impeller’s rotational speed and diameter. As the impeller spins faster, it generates greater centrifugal force, increasing the fluid’s velocity and flow rate. Jedoch, this relationship is not linear, as other factors like blade design and fluid viscosity also play a role.

The formula for flow rate (Q) is: Q = A × v, where A is the cross-sectional area of the pipe, and v is the fluid velocity. Since velocity depends on impeller speed and diameter, engineers must carefully balance these variables to achieve desired performance.

“The interplay between impeller speed and diameter is a cornerstone of efficient pump design.”

Impact of Measurement Units on Performance

Measurement units, such as feet or meters, can significantly impact system calculations. Zum Beispiel, using feet for diameter and meters for velocity requires careful unit conversion to avoid errors. Consistency in units ensures accurate flow rate calculations and system optimization.

- Impeller Diameter: Larger diameters increase flow rate but may require more energy.

- Unit Consistency: Using the same unit system simplifies calculations and reduces errors.

- Design Considerations: Engineers must balance speed, Durchmesser, and energy efficiency.

Practical Applications and Examples

Consider a pump with an impeller diameter of 0.5 meters rotating at 1200 Drehzahl. Using the flow rate formula, engineers can determine the system’s efficiency and make adjustments as needed. Such calculations are vital in industries like water treatment and manufacturing, where precise fluid movement is crucial.

By understanding these advanced concepts, professionals can design systems that maximize efficiency while minimizing energy consumption. This knowledge ensures reliable performance in both industrial and automotive applications.

Abschluss

Mastering the dynamics of rotational systems ensures peak performance in mechanical applications. Accurately determining speed is critical for optimizing pumps and superchargers, directly impacting efficiency and reliability. The formula breakdown and example walkthrough provide a clear roadmap for professionals to achieve precise results.

Revisiting the definition of tip speed highlights its role in evaluating system performance. Balancing this metric ensures operational safety and longevity. Utilizing dedicated online calculators simplifies the process, reducing errors and saving time.

By applying these principles, engineers can enhance system efficiency and reliability. Thoughtful exploration of these concepts ensures optimal performance in both industrial and automotive settings.