Choosing the right impeller is key when working with thick fluids. The design of the impeller greatly affects how well a system handles fluids. This is even more true when dealing with thick fluids. The choice between closed and open impellers can greatly change how well a system works.

When working with thick fluids, picking the right impeller is very important. Closed and open impellers have big differences. These differences are key to understanding which impeller is best for handling thick fluids.

Understanding Impeller Fundamentals in Fluid Processing

Fluid processing is key in many industries. Impeller fundamentals are vital for managing fluids well. Impellers handle various fluids, including thick ones, and picking the right one is important.

In fluid processing, impellers mix, blend, and pump fluids. Their design depends on the fluid type, flow rate, and needed pressure. Knowing these factors helps choose the best impeller for a task.

Basic Impeller Design Principles

Designing impellers involves looking at blade angle, pitch, and diameter. The blade angle affects fluid flow and pressure. Pitch and diameter influence efficiency and power use.

Role of Impellers in Fluid Management

Impellers are key in managing fluids. They mix, blend, and pump fluids well. They work with many fluids, from thin liquids to thick ones.

Impact of Viscosity on Impeller Selection

Fluid viscosity greatly affects impeller choice. For thick fluids, impellers need a bigger diameter and slower speed for better pumping and mixing.

Knowing impeller fundamentals is key for the right impeller choice. By looking at fluid type, flow rate, and pressure needs, industries can improve their fluid processing. This leads to better efficiency overall.

| Impeller Type | Fluid Type | Flow Rate | Pressure Requirements |

|---|---|---|---|

| Centrifugal Impeller | Low-Viscosity Fluids | High Flow Rate | Low Pressure |

| Positive Displacement Impeller | High-Viscosity Fluids | Low Flow Rate | High Pressure |

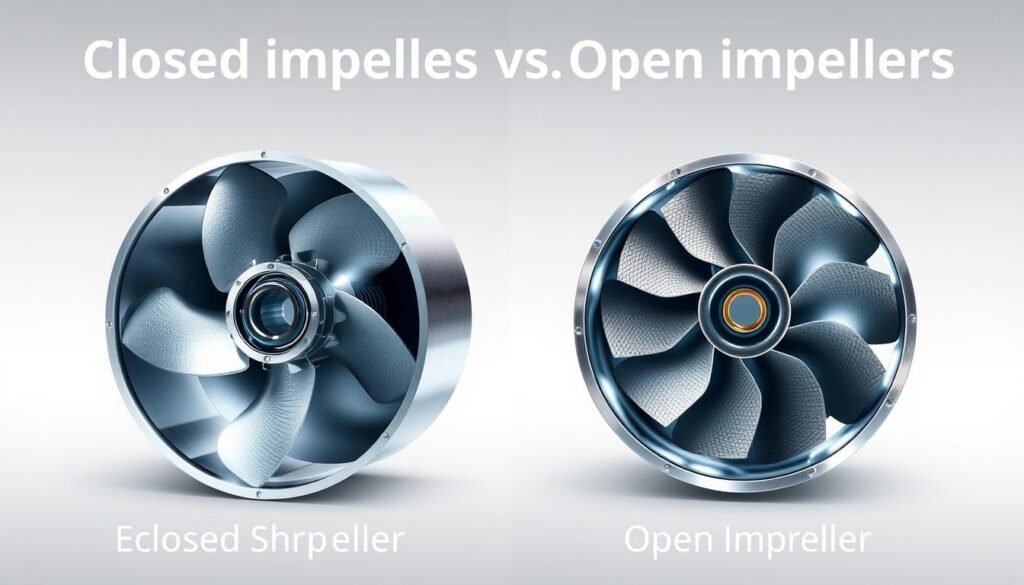

Key Differences Between Closed Impellers vs. Open Impellers

The type of impeller used in fluid processing greatly affects efficiency. Closed impellers and open impellers are two main types used across industries. Knowing the differences between them is key to picking the right impeller for a job.

A closed impeller is fully enclosed, leading to better efficiency and precision. In contrast, an open impeller is not fully enclosed, making maintenance and repair simpler. The choice between closed impellers and open impellers depends on the application’s needs, like the fluid type, flow rate, and pressure.

- Closed impellers work best with thick fluids, ensuring high precision and efficiency.

- Open impellers are better for thin fluids and are easier to maintain and repair.

In summary, the choice between closed impellers and open impellers depends on the application’s needs. By understanding their differences, industries can pick the best impeller for their fluid processing tasks. This ensures efficient and effective operation.

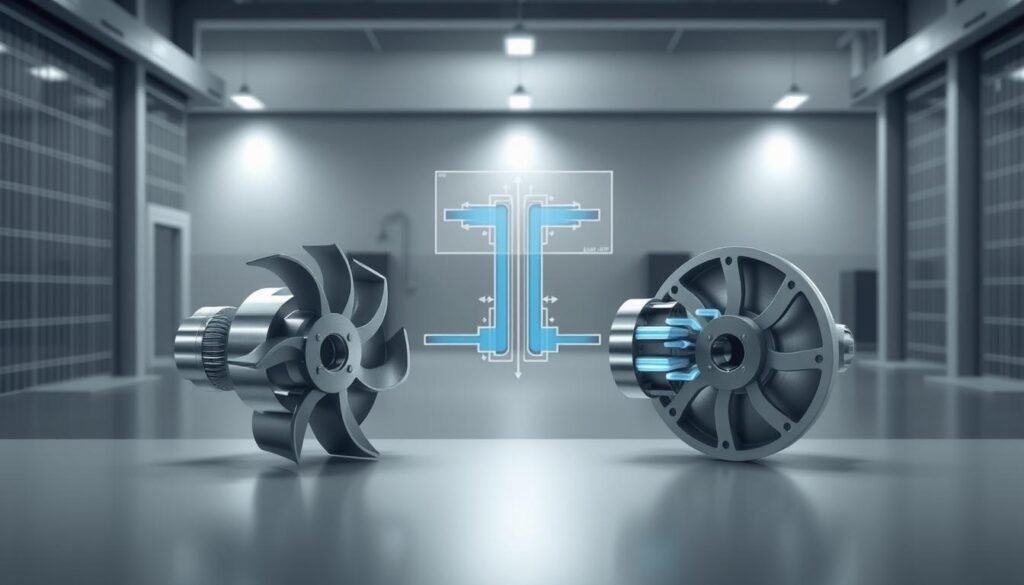

Performance Analysis in High-Viscosity Applications

Handling high-viscosity fluids shows big differences in closed and open impellers. Closed impellers are better at saving energy. This is key when you need to cut down on energy use.

Open impellers, on the other hand, can move more fluid. But, they might use more energy. It’s important to pick the right impeller for your needs.

- Shear force management: Closed impellers tend to generate higher shear forces, which can be beneficial for certain applications but may also lead to increased wear and tear.

- Pressure generation characteristics: Open impellers often produce higher pressures, which can be advantageous in certain contexts but may also result in increased energy consumption.

Looking at these points helps you choose the right impeller. This way, you can improve both energy efficiency and flow rate capabilities.

Maintenance and Operating Considerations

Choosing between closed and open impellers involves maintenance considerations. The design and materials used affect operating costs. For example, closed impellers might need more frequent maintenance due to their complex design. This can increase maintenance considerations.

On the other hand, open impellers may wear out faster. This can lead to higher operating costs over time. It’s important to think about maintenance considerations and operating costs for each impeller type. Here are some key points to consider:

- Material selection: The materials used can affect the impeller’s durability and maintenance needs.

- Design complexity: A simpler design can mean less maintenance and lower operating costs.

- Operating conditions: The impeller’s working conditions, like temperature and pressure, can impact its performance and maintenance considerations.

By carefully looking at these factors, operators can make better choices. This helps optimize their fluid processing systems.

Industry-Specific Applications and Case Studies

Choosing the right impeller type is key for any application. Each industry has its own needs and challenges. This makes it vital to pick the right impeller for the best results.

In the chemical processing industry, industry-specific applications demand impellers that can handle thick fluids and harsh chemicals. Closed impellers are often chosen here because they keep things contained and prevent contamination. In contrast, the food and beverage industry needs impellers for gentle mixing. Open impellers fit the bill here.

- Chemical processing: A leading chemical manufacturer switched to closed impellers and saw a significant reduction in maintenance costs and downtime.

- Food and beverage manufacturing: A major food processor implemented open impellers and achieved improved product quality and increased production efficiency.

- Pharmaceutical production: A pharmaceutical company selected closed impellers for their high-viscosity fluid handling capabilities and achieved compliance with strict regulatory requirements.

These examples show why it’s important to look at industry-specific needs and case studies when picking an impeller.

Conclusion: Making the Right Choice for Your Application

Choosing between closed and open impellers is key for handling thick fluids. Each type has its own benefits, like saving energy or better mixing. These choices can really change how well your system works.

The comparison of these impellers shows that the best choice depends on your specific needs. Things like how much fluid you need to move, the pressure you need, and how easy it is to maintain are important. By thinking about these, you can pick the right impeller for your job.

For anyone working with fluids, knowing about closed and open impellers is important. It helps you make smart choices that improve how you handle fluids. With the right knowledge, you can pick the best impeller for your job and get great results.