Accurate sizing of the impeller is critical for ensuring a pump operates efficiently. The impeller, a rotating component, plays a key role in generating flow and pressure within the system. Proper sizing directly impacts the flow rate and overall performance of the pump.

Manufacturer data and pump curves are essential tools for determining the correct size. These resources provide insights into how different diameters affect flow and head. For example, calculating differential pressure helps convert psi into head measurements, ensuring precise sizing.

Safety is also a priority when working with pump systems. Always follow guidelines to avoid errors that could lead to inefficiency or damage. In the following sections, we’ll explore detailed steps and examples to help you achieve optimal results.

Understanding the Importance of Impeller Diameter

The size of a pump’s rotating component directly influences its operational success. Proper impeller sizing ensures the system delivers the required flow and head, which are critical for efficiency. Incorrect dimensions can lead to higher energy consumption and reduced performance.

Impact on Pump Performance and Efficiency

Centrifugal pump design relies on precise impeller sizing to achieve optimal flow rate. When the size is too small, the pump struggles to meet demand, increasing energy use. Conversely, an oversized impeller can cause excessive pressure, leading to inefficiency and potential damage.

Incorrect sizing also affects water usage. For example, a mismatched impeller may force the pump to work harder, wasting both water and energy. This highlights the importance of accurate measurements in maintaining efficiency.

Role in Determining Flow and Head

Flow rate and head measurements are essential for pump performance. The impeller’s size directly impacts these factors, as it determines the volume of fluid moved and the pressure generated. Pressure differences must be carefully calculated to ensure the system operates within safe limits.

Suction and flow factors also play a key role in impeller selection. Proper sizing ensures the pump can handle the required volume without cavitation or other issues. Pump impeller specifications are vital for achieving consistent performance and longevity.

| Impeller Size | Flow Rate | Head | Efficiency |

|---|---|---|---|

| Small | Low | Low | Reduced |

| Medium | Optimal | Optimal | High |

| Large | High | High | Reduced |

Tools and Safety Measures

Safety and precision are essential when working with pump systems. Before taking any measurements, ensure the system is turned off and unplugged. This prevents accidental operation and reduces the risk of injury.

Gather the right tools for the job. A tape measure and pressure gauge are crucial for accurate sizing. These tools help verify dimensions and ensure the pump operates within safe limits.

Selecting the Right Measurements and Safety Precautions

Start by checking the pump’s information plate. This plate often lists pre-measured dimensions, saving time and effort. If measurements are missing, use a tape measure to determine the size directly.

Follow these steps for accurate measurements:

- Turn off and unplug the pump to ensure safety.

- Inspect the valve positions to confirm they are closed.

- Use a tape measure to measure the impeller’s width.

- Record the dimensions for future reference.

Handling pump components requires care. Avoid forcing parts or using excessive pressure. This prevents damage and ensures accurate results.

Common pitfalls like dead heading can cause inefficiency. To avoid this, ensure the system is properly primed and valves are correctly positioned. Regularly check the pump’s condition to maintain optimal performance.

| Tool | Purpose | Safety Precautions |

|---|---|---|

| Tape Measure | Measure impeller width | Ensure pump is off |

| Pressure Gauge | Monitor system pressure | Check valve positions |

| Information Plate | Verify pre-listed dimensions | Handle with care |

Centrifugal pump systems require extra attention. Follow manufacturer guidelines and industry standards to ensure safety and efficiency. Proper handling and accurate measurements are key to maintaining optimal flow and pressure.

Methodologies for Measuring Impeller Diameter

Measuring the rotating component accurately ensures optimal pump performance. Two primary methods are used: interpreting manufacturer information plates and using a tape measure for direct measurements. Both approaches are essential for achieving precise results and maintaining system efficiency.

Interpreting Manufacturer Information Plates

Manufacturer information plates are a reliable source for determining the size of the rotating component. These plates are typically located on the pump casing and provide pre-measured dimensions. Always check for this data before proceeding with manual measurements.

Here’s how to interpret the information:

- Locate the plate on the pump casing.

- Identify the listed dimensions, which often include the diameter.

- Verify the data against the pump’s operational requirements.

This method saves time and reduces the risk of errors. However, if the plate is missing or damaged, manual measurement becomes necessary.

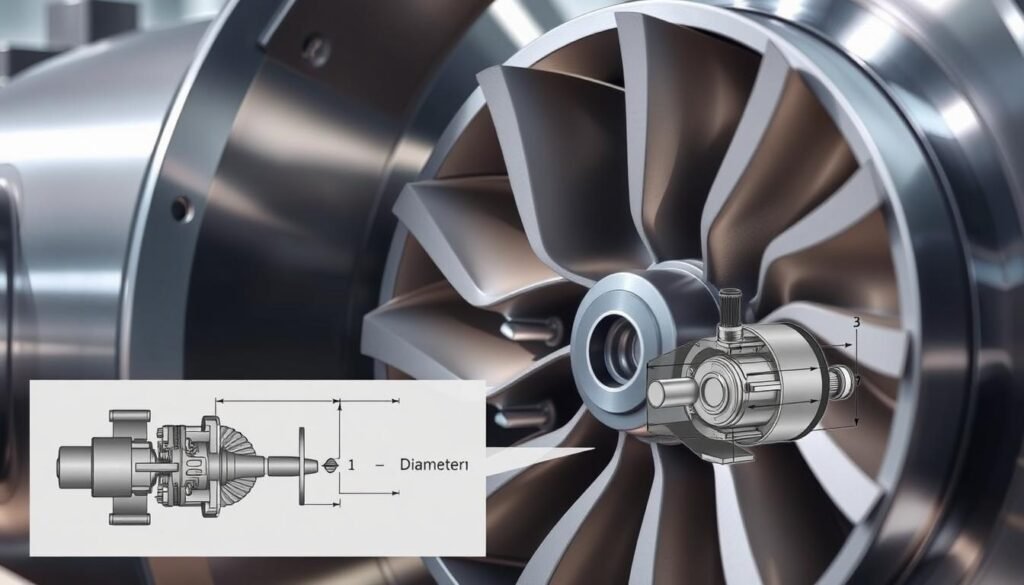

Using a Tape Measure for Direct Measurements

When manufacturer data is unavailable, a tape measure is the go-to tool. This method involves measuring from one blade tip to the tip directly opposite. Ensure the pump is turned off and unplugged before starting.

Follow these steps:

- Position the tape measure at one blade tip.

- Extend it to the opposite tip, ensuring it passes through the center.

- Record the measurement for future reference.

For example, a 6-inch reading indicates a specific size that can be used to calculate head and flow rate. Always double-check measurements to avoid inaccuracies.

Potential sources of error include misalignment or improper tool use. To minimize these risks, ensure the tape measure is straight and aligned with the center. Regularly calibrate tools to maintain accuracy.

Both methods are crucial for achieving precise sizing. Combining manufacturer data with manual measurements provides a comprehensive approach to maintaining pump efficiency.

How to find impeller diameter for pump: Step-by-Step Guide

Properly sizing the pump’s key component is essential for efficiency. This guide walks you through the process of determining the correct size using pump curves and manual measurements. Each step ensures optimal performance and energy savings.

Determining the No-Flow Point from the Pump Curve

Start by obtaining the pump curve from the manufacturer. This graph shows the relationship between flow rate and head. Locate the no-flow point, where the curve intersects the vertical axis. This point represents the maximum head the pump can generate without flow.

Next, record suction and discharge pressures. For example, if the discharge pressure is 65 psi and the suction pressure is 17 psi, calculate the differential pressure:

Differential Pressure = Discharge Pressure – Suction Pressure = 65 psi – 17 psi = 48 psi

Convert this pressure into head using the conversion factor 2.31:

Head (feet) = Differential Pressure × 2.31 = 48 psi × 2.31 = 110.88 feet

This calculation ensures the pump operates within safe limits and meets system requirements.

Measuring Blade Tips and Accounting for the Shaft

If manufacturer data is unavailable, measure the rotating component manually. Turn off and unplug the pump for safety. Use a tape measure to determine the distance between one blade tip and the opposite tip, ensuring the tape passes through the center.

For example, if the measurement from one blade to the opposite is 3 inches, double this to get the full size:

Full Diameter = 3 inches × 2 = 6 inches

Include the shaft measurement if necessary. Calibrate your results using the pump’s specifications to ensure accuracy. This step is crucial for maintaining efficiency and avoiding errors.

Here’s a summary of the process:

- Obtain the pump curve and identify the no-flow point.

- Record suction and discharge pressures to calculate differential pressure.

- Convert pressure into head using the conversion factor 2.31.

- Measure blade tips and double the measurement for the full size.

- Calibrate measurements using the pump’s specifications.

Common pitfalls include misalignment of the tape measure or incorrect pressure readings. Always double-check your measurements and calculations. Proper sizing ensures the pump operates efficiently, saving energy and reducing costs.

Practical Considerations and Common Pitfalls

Avoiding common mistakes can save time and energy in pump maintenance. Accurate measurements are essential for ensuring the system operates efficiently. Even minor errors can lead to significant issues, such as reduced flow or increased energy consumption.

Identifying Measurement Errors

One of the most frequent mistakes is misalignment when using a tape measure. Ensure the tool is straight and passes through the center of the rotating component. Overlooking shaft dimensions can also lead to inaccuracies. Always double-check measurements to confirm their validity.

Here’s a quick checklist to avoid errors:

- Use a calibrated tape measure for precise readings.

- Verify the shaft size if it’s part of the calculation.

- Record measurements immediately to prevent data loss.

Understanding Dead Heading

Dead heading occurs when the discharge valve is closed while the pump is running. This can cause excessive pressure, leading to damage. To prevent this, always ensure the valve is open before starting the system.

Operating with a closed discharge valve can lead to overheating and pump failure.

Efficiency Loss and Troubleshooting

Incorrect measurements can reduce the pump’s efficiency. For example, an undersized component may increase energy use, while an oversized one can cause cavitation. Regularly inspect the system to maintain optimal performance.

Follow these troubleshooting steps:

- Check valve positions to ensure they are correctly set.

- Monitor pressure levels using a reliable gauge.

- Re-measure the component if performance issues arise.

By addressing these common pitfalls, you can enhance the pump’s longevity and efficiency. Always adhere to manufacturer guidelines and safety precautions to achieve the best results.

Optimizing Pump Performance through Accurate Impeller Sizing

Optimizing pump performance starts with precise impeller sizing, ensuring systems run smoothly and efficiently. Proper adjustments based on flow rate and pressure conditions can significantly enhance energy efficiency and overall design. This section explores how fine-tuning impeller dimensions impacts performance and provides actionable strategies for achieving optimal results.

Adjustments Based on Flow Rate and Pressure Conditions

Analyzing flow rate and pressure conditions is the first step in determining if an impeller size adjustment is needed. For example, if the flow rate is lower than expected, reducing the impeller size can improve efficiency. Conversely, higher pressure demands may require a larger impeller to meet system requirements.

Here’s how to make adjustments:

- Review pump curves to identify the current flow rate and head.

- Compare these values with system requirements to identify discrepancies.

- Adjust the impeller size incrementally to achieve the desired performance.

For instance, a centrifugal pump operating at 50% efficiency might benefit from a 10% reduction in impeller size. This adjustment can reduce energy consumption while maintaining consistent water flow.

Enhancing Energy Efficiency and Overall Design

Fine-tuning the impeller diameter directly impacts energy efficiency. A properly sized impeller reduces power consumption and minimizes wear on the pump. For example, a pump impeller that’s too large can cause excessive pressure, leading to inefficiency and potential damage.

Key strategies for balancing water usage and rate consistency include:

- Monitoring system performance regularly to identify inefficiencies.

- Using pump curves to recalibrate impeller size based on changing demands.

- Ensuring the design factors, such as suction and head, align with operational needs.

For example, a pump operating at 100 psi might require a 6-inch impeller to maintain optimal flow. Regular monitoring ensures the system continues to perform efficiently over time.

| Impeller Size | Flow Rate (GPM) | Head (ft) | Energy Efficiency |

|---|---|---|---|

| 5 inches | 200 | 80 | High |

| 6 inches | 250 | 100 | Optimal |

| 7 inches | 300 | 120 | Reduced |

Accurate adjustments not only improve efficiency but also extend the pump’s lifespan. By focusing on design and pump impeller factors, operators can achieve optimal performance and reduce operational costs.

Conclusion

Properly sizing the rotating component ensures pumps operate at peak efficiency. Accurate measurements, whether using manufacturer data or a tape measure, are essential for optimal performance. Safety precautions, such as turning off the system before measurements, prevent accidents and errors.

Using pump curves and direct measurements helps determine the correct size, improving flow rate and pressure management. For example, a well-sized impeller enhances energy efficiency and reduces water waste. Regular monitoring ensures the system maintains its performance over time.

By following these guidelines, you can achieve better design choices and extend the lifespan of your centrifugal pump. For further assistance, consult manufacturer guidelines or seek professional advice to ensure your system operates at its best.